1. Structural form and characteristics of truncated conical helical spring

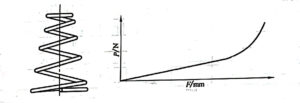

The spiral spring with the shape of a truncated cone is called the truncated cone coil spring, and the truncated cone coil spring is generally a compression spring. Its structure and characteristic lines are shown in Figure 12-3-1

Figure 12-3-1 Structure and characteristic lines of truncated conical helical springs

When the truncated conical helical spring bears the load, the force is proportional to the variation before the spring ring contacts, and the characteristic line segment on the P-F diagram is the straight line segment. When the load gradually increases, the spring coil starts to appear and die from the big end. With the increase of the parallel coil, the effective coil number decreases correspondingly, and the spring stiffness gradually increases until the coil is completely compressed. The relationship between force and deformation at this stage is non-linear, and the characteristic line segment on the P-F diagram is gradually increasing.

The rigidity of the truncated conical helical spring is variable, and the larger the conical Angle 0 is, the higher the change rate of the spring’s natural vibration frequency will be. For the relaxation or elimination of resonance, compared with the cylindrical helical spring, it can bear larger load and produce larger deformation under the same profile size, and the full compression is relatively small. If the cone Angle is large enough to make the difference between the big end radius R2 and the small end radius R1 (R2-R1)≥nd, then all spring rings can fall on the support seat when the spring is pressed together, and its compression height H=d. In addition, it has good stability when it is stressed, so it has greater lateral stability compared with the cylindrical spiral spring.