Wire Forming: Your Reliable Metal Wires Manufacturer

As a leading wire fabrication and spring manufacturer, we provide custom wire forming services (also known as wire bending) with decades of experience producing precision wire-formed components for global clients across all standard wire gauges.

CNC wire forming represents an advanced manufacturing method for creating intricate, dimensionally accurate metal wire configurations. As a trusted CNC wire forming manufacturer, we guarantee premium quality components, full-service production solutions, tailored customization, and guaranteed customer satisfaction.

In today’s demanding manufacturing landscape where precision engineering and adaptability are crucial, industrial wire forming emerges as an essential technology for producing sophisticated metal parts. From basic fasteners and clips to complex medical device components and automotive wire assemblies, this process serves critical applications across aerospace, electronics, healthcare, and transportation industries.

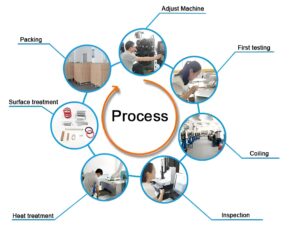

ChinaCustomSpring maintains an uncompromising commitment to manufacturing excellence. Our company implements rigorous quality control protocols throughout production stages. From raw material sourcing to final product testing, we strictly follow ISO-certified standards, consistently delivering components that surpass client specifications.

Metal wire fabrication employs multiple specialized techniques including precision bending, cutting, piercing, flattening, and coiling. Our facility utilizes state-of-the-art CNC wire bending machines, automated stamping presses, and secondary finishing equipment. Selective applications incorporate thermal treatment processes to achieve optimal material properties and surface finishes. Below we detail our core wire forming capabilities and service offerings

What is Wire Forming

Wire forming boasts an ancient heritage, tracing back to Bronze Age artisans who crafted elaborate gold jewelry. The craft evolved through medieval times before becoming a cornerstone of Industrial Revolution manufacturing.

The core principles of wire forming remain unchanged: wire is first drawn to precise dimensions, then shaped into functional components. However, modern wire forming technology—particularly in the 20th century—has revolutionized tools, techniques, and material options.

Precision wire forming transforms metal wire into essential parts like springs, clips, and retaining rings. While most wire features a round cross-section, specialized variants include flat wire, square wire, rectangular wire, and even trapezoidal profiles for unique applications.

Wire terminology can be confusing. Metal lengths with 10 mm to 100 mm diameters are often classified as rods, while thicker pieces are called round bar stock. However, these labels are flexible—rods may still undergo wire forming processes when precision shaping is required.

Before forming, wire must be drawn through a die to achieve exact dimensions. This die features a tapered opening that gradually compresses the wire’s diameter. Operators carefully control tension to prevent breakage or over-stretching, often using multiple dies for incremental sizing until specifications are met.

In industrial wire forming, drawn wire is straightened via roller systems, then shaped using specialized tooling. For example, producing a bent pin involves guiding wire over a forming tool to create precise angles before cutting it to length. Additional steps may include hole punching, drilling, or end chamfering for finished functionality.

Wire Forming Process

The wire forming process involves various techniques to shape wire into intricate three-dimensional forms. In addition to bending, wire forming includes

-Upsetting (compression in the axial direction): This is a forging process where the length of a wire or metal workpiece is shortened and its diameter is increased by applying compressive force along its axis. It’s commonly used to create heads on fasteners like bolts and rivets.

–Extrusion (forcing wire through a narrow opening): Extrusion involves pushing or drawing a metal wire through a die of a desired cross-section. This process is used to create objects of a fixed, often complex, cross-sectional profile, and is widely utilized in the production of wires, tubes, and various structural shapes.

-Swaging (shaping and side pressing): Swaging is a process that reduces or shapes the diameter of wire or tubing by hammering or pressing. It can also be used to join wires or cables by deforming them to fit together, often without the need for additional fasteners.

-Stamping (using dies to bend and shape wire): Stamping is a manufacturing process that uses dies to transform flat wire into specific shapes. The wire is placed in a stamping press where a tool and die surface form the metal into a net shape by bending, punching, or cutting.

-Twisting (combining lengths and creating specific shapes): Twisting involves twisting together two or more lengths of wire to create a specific shape or to increase the strength and flexibility of the wire. This technique is often used in the manufacture of cables, ropes, and reinforced hoses.

-Stretching (elongating and thinning wire): Stretching is a process where wire is pulled through a series of dies to elongate and thin it to the desired diameter. This cold working process increases the tensile strength and hardness of the wire while reducing its cross-sectional area.

As s professional manufacturer,we also use roll forming, welding, knurling, chamfering, and weaving to create complex parts.

Custom Wire Forming Ability

We possesses a wide range of capabilities in CNC wire forming. With advanced machinery and skilled technicians, they can handle various types of wires, including stainless steel, carbon steel, aluminum, brass, and copper. Whether it’s simple or complex wire shapes, the manufacturer can produce them with precision and accuracy.

-Wire Diameter :

From 0.1~20mm .

We have many kinds of machine from small to big power, which enable us to make large range of diameter. We are confident to say that almost common diameter can be done by us.

-Material:

- Titanium,

- Carbon steel,

- Silver, Nylon, Cr5, Iron, Nickel plated carbon wire, Nickel plated steel wire harp,

- Flat wire,

- Square wire,

- SUS304/316/302 ,

- Spring steel 72A, 65Mn,82B,

- 55CrSi,

- 60Si2Mn alloy steel,

- inconel X750 steel,

- music wire,

- phosphorus copper wire etc.

When selecting a material for wire forming, it is essential to consider factors such as the intended application, operating environment, budget constraints, and regulatory requirements. Conducting thorough research and consulting with materials experts can help manufacturers make informed decisions regarding the choice of material for their wire forming needs.

The right material is a critical step in the manufacturing process. By choosing the appropriate material based on the specific requirements of the project, manufacturers can ensure the production of high-quality wire formed products that meet industry standards and customer expectations.

-Surface Treatment:

- Zn-plating,

- Ni-plating, Cr-plating, Tin-plating, copper-plating,

- the wreath oxygen resin spraying,

- the heat disposing,

- hot-dip galvanizing,

- black oxide coating, painting, powdering,

- color zinc-plated, blue black zinc-plated,

- rust preventive oil,

- titanium alloy galvanized,

- silver plating, plastic,

- electroplating,

- anodizing etc.

surface treatment plays a vital role in enhancing the quality and performance of wire forming parts. By utilizing the appropriate surface treatment method, manufacturers can ensure the production of high-quality wire formed products that not only meet industry standards but also exceed customer expectations in terms of functionality and aesthetics.

Wire Forming Applications:

Wire forming is a versatile manufacturing process used across countless industries, delivering critical solutions for everything from basic components to complex wire assemblies. Renowned for durability, cost-efficiency, and design flexibility, precision-formed wire parts serve essential roles in these key sectors:

- Automotive Industry

Wire-formed components like suspension springs, retaining clips, mounting brackets, and seat mechanisms are vital to vehicle performance. High-grade automotive wire springs ensure smooth suspension operation, while precision clips and brackets provide secure fastening for electrical systems and interior assemblies.

- Medical Industry

The medical device industry depends on surgical-grade wire forming for biocompatible instruments, catheter guides, and orthopedic implants. These high-precision wire components meet strict FDA standards, enabling safer diagnostics, minimally invasive surgery, and improved patient rehabilitation devices.

- Aerospace Industry

Aerospace applications demand lightweight yet high-strength wire forms, including aircraft harnesses, avionics connectors, and engine compartment brackets. These flight-critical components undergo rigorous testing to ensure reliability under extreme conditions.

- Electronics Industry

Precision wire connectors, PCB terminals, and shielding assemblies enable seamless electrical conductivity in consumer electronics, 5G infrastructure, and industrial automation systems. Their miniaturized designs support faster data transmission and compact device layouts.

- Furniture Industry

From reinforced chair frames to modular wire shelving, steel wire forms combine structural integrity with sleek aesthetics. Commercial displays and storage solutions benefit from their rust-resistant coatings and weight-bearing capacity.

- Industrial Machinery

Heavy-duty wire guards, conveyor system guides, and tooling fixtures enhance safety and efficiency in factories. Custom wire baskets streamline part handling, while welded wire screens protect sensitive equipment.

- Retail & Display

Merchandising wire forms—including slatwall hooks, gondola shelving, and POS displays—maximize retail space utilization. Their modular designs adapt to seasonal layouts while maintaining product visibility.

-Packaging:

Inner plastic bag, outer carton box, and we can also pack products according to your requirements.

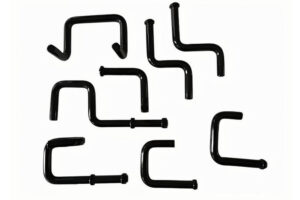

-Main Products:

- Compression spring,

- Cotter Pins and Split Pins

- Bridge Pins

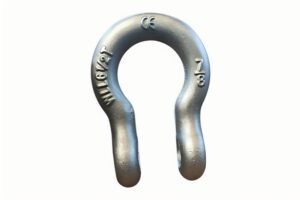

- D Rings and D Clips

- S Hooks and V Hooks

- C‑Form Rings

- Heavy Duty Split Retaining Rings and Keyrings

- Extension spring,

- Torsion spring ,

- Coil spring,

- leaf spring,

- stamping part,

- etc.

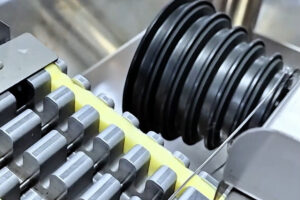

-Producing Equipment:

- Spring machine Jinju & 502S(Spring coiling machine, Pressure spring machine, CNC computer spring omnipotent machine, grinding machine,automatic spring machine etc.).

- Other machines including Screw machine Hexing/SX & H series,

- Shaft machine Liqiang ,

- Auto lathes Libo & XB ,

- CNC machine SHENGYU & SYX42,Inclinable press machine WORLD & J23-80/ J23-65A/J23-16,Milling machine COYO/ALSGS & CY-L-90,

- Continuous hot wind tempering furnace Sanli & RJC210 ,

- Tapping machine Dongrong/EF,Grinder machine DA SHUANG YANG & M230-2,

- Lathe machine C6233 ,

- Wire cutting machine Deren & DK7740 etc.

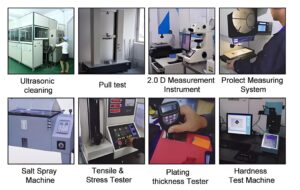

-Testing Equipment:

- Projecting Apparatus,

- Salt Spray Test,

- Durometer,

- Coating Thickness Tester

-Quality Control

A group of experienced production technician, sophisticated engineer and dedicated QC.

-Main Markets

- North America,

- South America,

- Eastern Europe ,

- West Europe ,

- North Europe,

- South Europe,

- South Asia,

- Africa African

Our Wire Forming Services

Wire forming combines precision engineering with creative craftsmanship, transforming metal wires into custom shapes and sizes for diverse applications. The science of wire forming relies on advanced metallurgy to understand material behavior under stress, while the art of wire forming delivers both functional performance and aesthetic appeal in finished products.

This versatile manufacturing process serves industries ranging from high-tech aerospace to luxury jewelry design. From medical device components to automotive springs, precision wire forming enables custom solutions for specialized needs. Its adaptability also makes it ideal for personalized gifts and architectural decor.

Partnering with a professional CNC wire forming manufacturer in China offers key advantages: superior quality, full customization, and dependable OEM/ODM services. Our factory combines strict quality control, multi-industry expertise, and flexible production to deliver high-performance wire forms—from simple brackets to complex assemblies—meeting your exact specifications.

How to Place an Order

- Submit Requirements: Share your technical drawings or physical samples

- Project Evaluation: Our engineers conduct feasibility analysis

- Design & Quote: We provide 3D prototypes and competitive pricing

- Confirmation: Approve the design and quotation

- Prototyping: We airmail production samples for verification

- Order Finalization: Confirm after sample approval

- Production: Manufacturing begins after 30% deposit

- Quality Assurance: Submit inspection reports before shipment

- Delivery: Balance payment followed by global logistics

Custom-Made Springs