Basic Types of Circlips

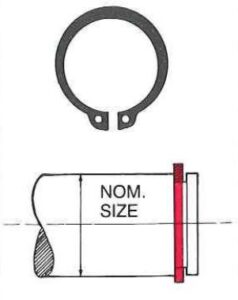

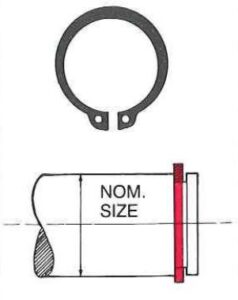

External Circlip

Circlips are designed to prevent lateral movement and serve as retaining rings in bearing assemblies. They are made from semi-flexible metal and have a circular shape with a clip, open at one end.

The most common type is the axially fitted circlip for shafts with grooves. These circlips are constructed as curved beams of uniform strength, with the radial width tapering towards the free ends to maintain a consistently round shape during continuous use. This design is particularly effective in assemblies exposed to strong centrifugal forces, ensuring stability at high rotational speeds. Lugs with holes allow for quick installation and removal using circlip pliers.

Materials:

- Carbon Spring Steel – Finish: Phosphate and Oil

- Stainless Steel – Grades: 1.4122, 1.4543-Aero

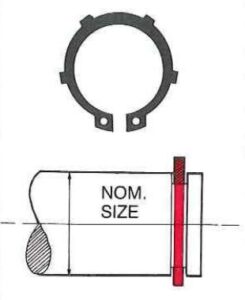

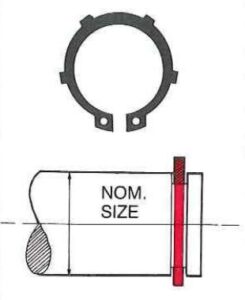

External Circlip Lugged

Compliant with DIN 983, installed axially on shafts with grooves, this variant shares the standard design but includes evenly spaced protrusions around the outer diameter. These protrusions help ensure consistent contact with radiused or chamfered components for shafts ranging from 16mm to 140mm.

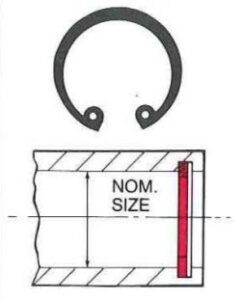

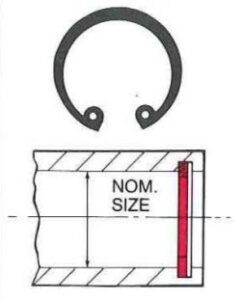

Internal Circlip Standard

Type B internal circlips are designed to prevent lateral movement of assembly components within a bore. Crafted from high-quality spring steel or stainless steel, we provide these circlips in a wide range of sizes, dimensions, and thicknesses to fulfill our clients’ specific requirements. Each product undergoes rigorous testing based on various parameters.

These circlips are suitable for most standard engineering applications, serving effectively as a rigid shoulder within a bore.

Materials:

- Carbon Spring Steel – Finish: Phosphate and Oil

- Stainless Steel – 1.4122, 1.4543-Aero”

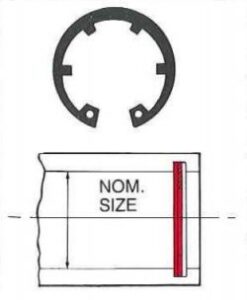

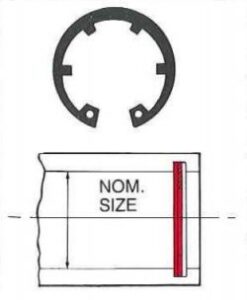

Internal Circlip Lugged

Compliant with DIN 984, this variant is axially fitted to bores with grooves, mirroring the standard design but featuring additional evenly spaced lugs around the inner diameter. This characteristic helps ensure reliable contact with radiused or chamfered components for bores ranging from 16mm to 170mm.

Type E Circlips – DIN 6799

We provide an extensive selection of E type circlips.

These radially fitted circlips are the most commonly used for shafts with grooves, offering a substantial shoulder on a relatively small shaft diameter. Our range can be supplied stacked on rods, suitable for use with applicators and dispensers, allowing for rapid installation and significantly reduced assembly costs.

For this type of circlip, only the groove size is critical, while the shaft diameter can vary widely.

Snap Rings

Axially fitted snap rings are designed for shafts with semi-circular grooves and are primarily utilized in the assembly of needle bearings, needle cages, and sealing rings.

These snap rings are mainly applied in semi-circular grooves alongside quarter-circle coverage of the corresponding mating component.

Applications:

- Securing gudgeon pins (special shapes)

- Gear systems

- Automotive engineering

- Auxiliary installation elements

- Fittings industry”

What are Circlips, Their Types, and Applications

What are Circlips, Their Types, and Applications