Extension Springs

At our company, we take pride in being a reputable and professional manufacturer of extension springs. With our expertise, experience, and commitment to quality, we have established ourselves as a trusted provider of high-performance extension springs for a wide range of industries.

The Extension springs (also called a pull spring,tension spring) is a spiral spring that bears the axial tension. The tensile springs are usually made of circular cross section materials. In the absence of load, there is no gap between the ring and the ring of a stretch spring.

Overview of Extension Springs

Extension springs are utilized in a diverse range of applications requiring precise force at specific deflections. These springs are employed for retracting aircraft landing gear, securing equipment to offshore oil rigs, and as hood-assist springs for heavy trucks. They are also used for specialized security barriers in roadways and buildings. Extension springs vary widely in length (ranging from 1/2-inch to 50 feet) and the force they generate (from a few ounces to thousands of pounds).

Operation of Extension Springs

Extension springs are designed to store and absorb energy while providing resistance to pulling forces. During manufacturing, the wire is rotated backwards to create “initial tension,” determining the tightness of the coils. Pulling the spring apart undoes this rotation, developing force or initial tension. This initial tension can be adjusted to meet specific load requirements.

Heavy-Duty and Small Extension Springs

Heavy-duty extension springs are built to withstand substantial loads and challenging environments. We offers expert design assistance to optimize their performance and lifespan. For small extension springs with ODs smaller than 0.500″(12.7mm), we provides customizes springs based on specific requirements by customer.

Our Extension Springs

Our custom-made springs are wound with initial tension to provide secure installation holding. The initial tension is the minimum force required to separate adjacent coils. Each spring features a constant diameter with various hook/loop styles. Tolerances for extension spring rates depend on the body and wire diameter, typically within +/- 10% and +/- 5% on the diameter. Please note that initial tension is challenging to control and is provided as a reference value only.

Extension Spring Manufacturing

When it comes to extension spring manufacturing, you can rely on our industry-leading expertise. Our teams consist of experienced manufacturing technicians and engineering experts dedicated to creating customized products tailored to your requirements. We have the capability to produce extension springs of different thicknesses and lengths using both cold and hot coiling processes.

Another benefit of partnering with us is our extensive stock of various alloys. This allows us to efficiently develop a couple of prototypes in-house, offering a cost-effective solution for our customers.

Core Attributes of Extension Springs

To fully understand the functionality of an extension spring, it is crucial to examine its fundamental physical properties. These attributes determine how the spring performs under load and are essential for selecting the appropriate spring for any application.

1. Wire Diameter

The wire diameter refers to the thickness of the material used to construct the spring. A thicker wire generally increases the spring’s load-bearing capacity but reduces flexibility. Precise measurement is critical, as even minor deviations can significantly impact performance.

2. Outer Diameter (OD)

The outer diameter is the measurement across the spring’s widest point, from one outer coil edge to the opposite side. This dimension is vital for ensuring the spring fits correctly within an assembly or housing.

3. Inner Diameter (ID)

The inner diameter represents the open space within the coils and is crucial when the spring must fit around another component, such as a rod or shaft. It can be calculated by subtracting twice the wire diameter from the outer diameter (ID = OD – 2 × Wire Diameter).

4. Length Inside Hook

This measurement indicates the distance between the inner edges of the spring’s hooks or loops. Proper sizing ensures secure attachment to other components, prevents overstressing the hooks, and guarantees correct installation within the assembly.

5. Total Coils

The total number of coils in the spring body influences its flexibility and energy storage capacity. More coils typically result in greater elasticity and a lower spring rate (the force required to stretch the spring), while fewer coils increase stiffness and require higher force for extension.

6. Initial Tension

Unlike compression springs, extension springs are manufactured with built-in initial tension, keeping the coils tightly wound even in an unloaded state. This force must be overcome before the spring begins to extend. Initial tension acts between the coils—when the spring is stretched, this force is applied first before the standard spring rate (k) takes effect. Accurate force calculation requires adding the initial tension to the spring rate’s contribution.

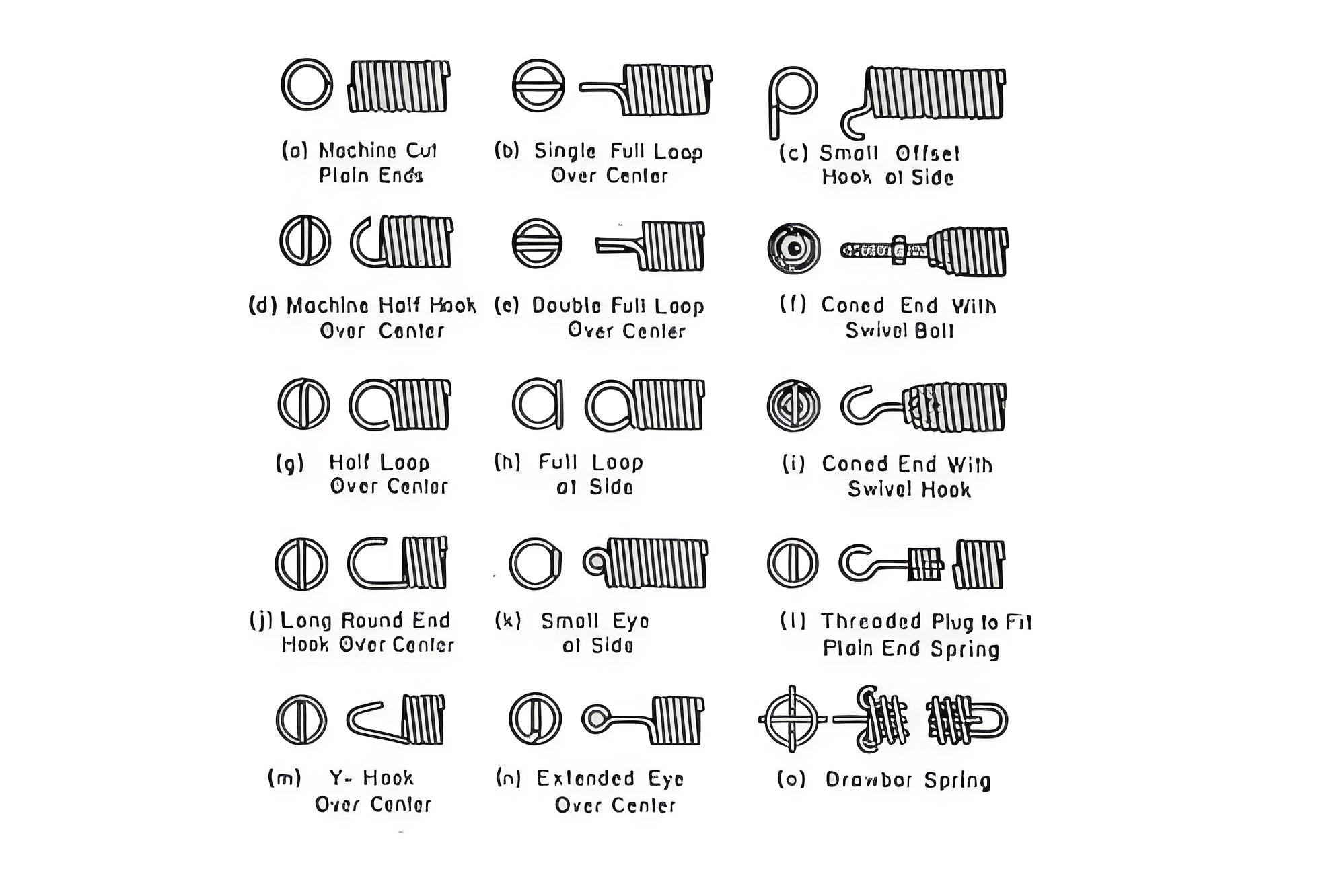

Extension Spring End Types

The end type of an extension spring is a critical design feature that determines how it connects to other components in an assembly. These ends—typically hooks or loops—allow the spring to attach to fixtures, rods, or mounting points, enabling it to stretch and return to its pre-loaded state. Different end types vary in strength, durability, and application suitability. Below are the most common hook configurations for extension springs:

1. Machine Hooks

Machine hooks are among the most widely used end types due to their strength and reliability. They are formed by bending approximately ¾ of a coil outward, creating a sturdy connection point. The bend radius is less pronounced than in other hook types, enhancing durability and load-bearing capacity. This robust design makes machine hooks ideal for heavy-duty applications involving high forces and repeated cycling, ensuring long-term performance without premature failure.

2. Cross Over Center Hooks

Cross over center hooks feature a more pronounced bend compared to machine hooks. The last coil is lifted and twisted inward, crossing over the spring’s centerline. This design provides a centrally aligned attachment point, improving force distribution and stability. While slightly simpler to manufacture than machine hooks, cross over center hooks excel in applications requiring precise alignment and controlled tension, as the crossing loop helps evenly distribute stress.

3. Side Hooks

Side hooks are designed for applications where the spring body must avoid interfering with adjacent components. The hooks are bent to one side, offsetting the spring from its mounting points. This simple and economical design is created by bending the last coil outward, making side hooks cost-effective yet reliable. They are commonly used in space-constrained mechanisms where unobstructed spring movement is necessary.

4. Extended Hooks

Extended hooks function similarly to side hooks but feature a longer reach, allowing for greater length inside the hook while maintaining a compact spring body. This design is beneficial when additional clearance is needed between the spring and its mounting points. However, due to their complex manufacturing process, extended hooks are the most expensive option. They are often selected for precision applications requiring both high force and space efficiency.

5. No Hooks (Hookless Ends)

Some extension springs are designed without hooks, offering unique advantages:

-

Increased Lifespan: Eliminating hooks removes stress concentration points, reducing fatigue and extending service life.

-

Cost Efficiency: Simplified manufacturing lowers production costs.

-

Higher Load Capacity: Without hooks, the spring can handle greater forces and longer travel distances.

-

Alternative Attachment Methods: The spring can be secured using bolts threaded through its inner diameter, avoiding hook-related failures.

Hookless springs are ideal for high-stress, high-cycle applications where durability and performance are critical.