Die Springs

We are a leading China-based manufacturer of springs and offer a wide range of die springs made from both oil-tempered and chrome-alloy materials. Primarily used in die machinery, these kind of springs are also suitable for various applications requiring high-static or shock-load stresses, as well as those necessitating maximum cycle-life.

To optimize design space, we utilize rectangular wire to decrease solid height. Our production encompasses die cut springs crafted from both round and rectangular wire.

Our company provides custom-made and standard die springs to meet diverse requirements.

Die Springs Overview

It is also called the rectangular spring, because the section of the material is rectangular, so it is called the rectangular spring.

Such springs is the spring brand produced by the United States union spring company, and the United States spring company is the largest precision spring manufacturer in the world. The rectangular springs are famous for many years with stable performance. The rectangle spring is very suitable for occasions with high load and limited space.

Die Spring Characteristics

Before you start purchasing for die springs, it’s important to understand some key characteristics.

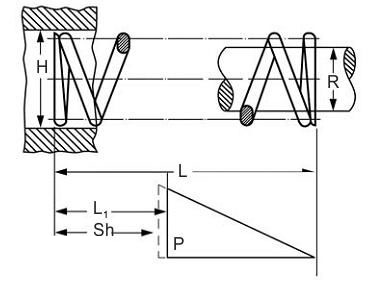

This spring is primarily defined by its geometric properties, including Free Length, Hole Diameter (the size of the housing where the spring fits), and Rod Diameter (the size of the shaft that fits inside the spring). They feature wire diameters with rounded-edge rectangular cross sections, which are significantly thicker than traditional circular wire compression springs.

The Spring Rate of a die spring indicates the force needed to compress it by a specified length, usually expressed in lb/in, which represents the force required to compress the spring by 1 inch. Typically, die spring rates are much higher than those of standard compression springs.

A color-coding system helps identify unfinished die springs for easy recognition in manufacturing settings. For instance, Light-Duty die springs made from chrome alloy are blue, while extra-heavy-duty options are green.

How to Select a Die Spring

When selecting die springs, remember the essential geometric characteristics discussed earlier. Other design features, such as duty load rating and free length, are also crucial.

Once you have a clear idea of the required geometry, assess the load your spring will need to handle. With this information, you can choose die springs based on their spring rates to determine the linear displacement in your application. This will help you understand how the spring will function within your machine design, both when loaded and unloaded.

For more information on selecting a die spring that meets your specifications, please send us email for details.

Die Springs Material

The material is usually to be Alloy. The high quality chromium alloy steel die spring product has the largest bearing capacity and longer service life.

The material is used to combine the spring steel SV9254, chrome silicon alloy rectangular steel wire and grind. Texture of material SAE6150 -750, INCONEL INCONEL, chrome vanadium steel -718, Nimonic 90, Nimonic 90.

Temperature range -46 C ~ 300 C