Basic knowledge of spring

Brief introduction of Spring

1.What is a spring?

A spring is a mechanical part that uses the elasticity and structural characteristics of the material to deform and store energy.

Classification of springs

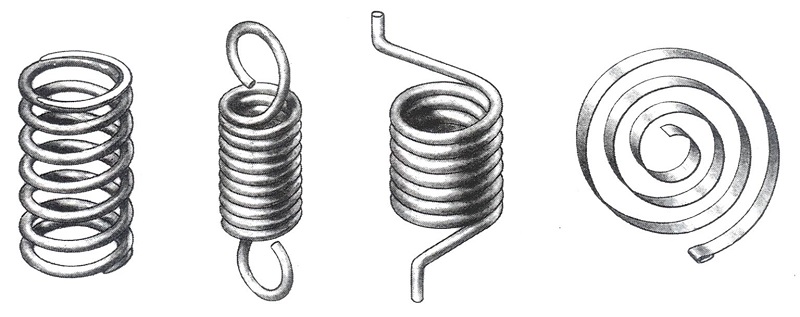

Generally divided into three categories: coil springs (including compression springs, tension springs, torsion springs)

Scroll spring,Circlip, serpentine spring, leaf spring,Front and rear shock absorber springs,Clutch spring, valve spring

Terminology of spring

Working load: the force or torque that the spring bears during the working process

Ultimate load: the load corresponding to the yield limit of the spring material

Working limit load: the maximum load that may occur during spring operation

Compression and load: the theoretical load when the spring is compressed

Deformation: the relative displacement of the spring along the direction of the load

Stiffness: spring load that produces unit deformation. Formula (A-B) * stiffness = force value

Initial tension: The internal force formed by a dense coil tension spring when it is cold-rolled. Its value is the force required when the spring begins to produce tensile deformation.

Free height: height/length of the spring without load

Free angle: the angle between the two arms when the torsion spring is unloaded

Compression height: the theoretical height when the compression spring is compressed to the contact of each circle

Pitch: the axial distance between two adjacent effective coils of the coil spring

Pitch diameter: the average value of the inner diameter and outer diameter of the spring

Winding ratio: the ratio of the pitch diameter of the coil spring to the material

Total number of turns: the number of spiral turns between the two ends of the spiral axis

Effective number of turns: the number of turns when calculating the spring stiffness

Number of supporting turns: the number of turns used for supporting or fixing at the end of the spring

Total number of turns = effective number of turns + number of supporting turns

2.Process method

2.1. Settlement

A process in which the heat-treated compression spring is compressed to the height under the working limit load or compressed and compressed one or more times to achieve the spring size as the main purpose.

2.2. Strong pressure

Compressing the spring to the surface of the spring material produces beneficial residual stress that is opposite to the working stress, so as to achieve a process method that improves the spring load-bearing capacity and stabilizes the geometric size.

2.3. Fatigue test

A test to assess the fatigue performance of a spring.

3. Classification of spring materials:

Generally divided into: carbon steel, alloy steel, stainless steel, copper alloy…..

3.1 Carbon steel: 65Mn 72A 82B T9A 70C 80C 72B SWC…

3.2 Alloy steel 55CrSi 9254 60SI2Mn

3.3 Stainless steel SUS301 (304 302 303 321) 1Cr18N9…

3.4 Steel alloy, phosphor bronze, brass, silicon bronze, tin bronze, beryllium bronze

3.5 piano wire: SWP SWP-B

4.Coils

4.1. Total number of turns = effective ring + number of supporting turns

Under normal circumstances, the two support rings each have 1 ring

4.2. The total number of close coil springs and sparse coil springs = effective number of coils

4.3. Tightly (closely) 1 circle=2 circle

5.Diameter

Pitch diameter: the average value of the inner diameter and outer diameter of the spring

Wire diameter: the original diameter of the material steel wire

Outer diameter = inner diameter + two wire diameters

= Pitch diameter + 1 wire diameter

Pitch diameter = outer diameter-1 wire diameter

= Inner diameter + 1 wire diameter

Inner diameter = outer diameter-2 wire diameters

= Pitch diameter-1 wire diameter

Wire diameter=(outer diameter—inner diameter)/2

= Pitch Diameter-Inner Diameter

= Outer Diameter-Pitch Diameter

6.rotation direction:

left-handed and right-handed

7.heat treatment

7.1 Carbon steel: After heat treatment, the outer diameter becomes smaller, the number of turns becomes more, and the length becomes shorter

7.2 Stainless steel: After heat treatment, the outer diameter becomes larger, the number of turns becomes less, and the length becomes shorter

7.3 Alloy steel: After heat treatment, the outer diameter becomes smaller, the number of turns becomes more, and the length becomes shorter

8.the problems that are prone to spring appearance

8.1 Compression spring: opening, scratching, deformation, uneven head, cutting the second line, flattening line, closing, too much/small dense circle, drape, poor flatness and verticality, etc.

8.2 Torsion spring: opening, scratching, deformation, concave and convex head, cutting the second line, flattening line, closing, too much/small dense circle, draped front, R position too dead angle, cracks at the hook.

8.3 Tension spring: opening, scratching, deformation, concave-convex head, cutting the second line, flattening line, draped front, loose loop, large/small force, etc., pay attention to the spring requirements for side hook/middle hook, opening direction And angle.

Remarks: All springs need to pay attention to the presence or absence of front.

9. Technological process

General process flow: check-picking-adjusting machine-confirming-starting-inspection-heat treatment-warehousing

Special process: surface oxidation, oil spraying, cleaning, hand processing, shot peening, tempering, grinding, polishing and other requirements are required before/after heat treatment.