Development of spring manufacturing

The application of spring is very early. The earliest application is probably bow and arrow, which can be traced back to the era of primitive man in human evolution. It has been nearly hundreds of years to use spring made of metal materials alone.

Before liberation, China’s spring processing equipment manufacturing industry was almost blank. Most steel wire springs were wound by hand, and large springs of hot coil were also hammered by forgers. In the railway transportation system with large demand, only a small amount of backward machinery and equipment from the 1930s are used, which can not meet the needs in terms of output or quality. Domestic spring coiling machine was developed in the late 1950s and early 1960s, and developed rapidly after the 1970s. In the early 1990s, the introduction of foreign advanced technology and the emergence of computer servo spring coiling machine played a very positive role in promoting the development of spring equipment in China. At present, China’s spring manufacturing industry is becoming more and more mature and perfect, and will continue to learn foreign advanced technology, summarize experience, enhance exchanges and cooperation, and catch up with and surpass the world’s advanced level.

The development of spring coiler has probably gone through the following stages:

1. Original simple spring coiling machine

2. Single shaft, single speed motor spring coiler

3. Cored spring coiler

4. Coreless automatic spring coiler

5. Various special automatic spring coiling machines

6. Microcomputer controlled automatic spring coiling machine

In short, the development of spring coiling machine is also from scratch, from simple to complex, and then from complex to simple. It follows a spiral development process, and the spring processing equipment is becoming more and more perfect.

Common equipment for spring manufacturing

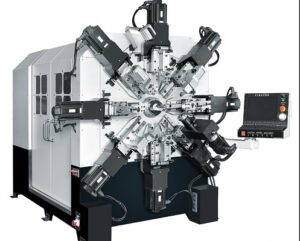

Spring processing equipment is divided into cold coil equipment and hot coil equipment according to the size of material diameter. Cold coiling equipment is applicable to cold drawn spring steel wire and wire rod with diameter less than 20mm. This equipment includes semi-automatic spring coiling machine, automatic spring coiling machine (mechanical type), NC spring coiling machine, vertical and horizontal spring grinding machine (mechanical and NC), straight tail spring coiling machine, bending machine, straightening machine and shot peening machine. Hot coil equipment is applicable to bars above 20mm, including hot coil spring machine, heavy spring coil spring machine, tip grinding machine and heating furnace.

Custom springs

Follows are some details for the springs we make.