Copper Wire Forming: Crafting Custom Springs with Precision

As a professional custom spring and wire forming manufacturer, we take pride in our ability to craft high-quality products that meet the unique needs of our clients. Our skilled engineers and technicians specialize in Copper Wire Forming, using cutting-edge technology and innovative techniques to ensure precision and accuracy in every piece we made.

What is Copper Wire Forming?

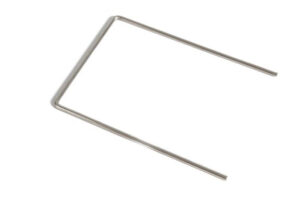

It refers to the process of shaping copper wire into a specific form or shape. This can be done using a variety of techniques, such as bending, twisting, coiling, and more. Copper wire is a popular choice for wire forming due to its high conductivity, durability, and resistance to corrosion.

Our Expertise in Wire Forming

Our team of experts has years of experience in copper wire forming, allowing us to create custom springs and wire forms that meet the exact specifications of our clients. We use advanced computer-aided design (CAD) software to create 3D models of our products, allowing us to test and refine our designs before manufacturing. This ensures that our clients receive high-quality, reliable products that meet their exact needs.

Benefits

There are many benefits to using copper wire bending for your custom spring and wire form needs. Copper wire is highly conductive, making it ideal for use in electrical applications. It is also resistant to corrosion and has excellent durability, allowing it to withstand harsh environments and heavy use. Additionally, copper wire is easily malleable, making it easy to shape and form into intricate designs.

Applications

It can be used in a wide variety of applications, including automotive, aerospace, medical, electronics, and more. Custom springs and wire forms can be used for everything from electrical connectors to suspension systems, and are often used in high-stress environments where durability and reliability are essential.

Custom Wire Forming

|

Item

|

Custom design wire bending (also called wire forming)

|

|

Style

|

Cylinder, Flatten, Rounded, Customized

|

|

Material

|

Spring steel (SWC), Music wire(SWP),Alloy steel,Mild-carbon steel,

72A,65Mn and so on

|

|

Sample

|

available

|

|

Wire diameter

|

from 0.1 to 11.0 mm

|

|

Type

|

Compression; Torsion; Extension springs; CNC Machining…

|

|

Surface treatment

|

Electronic Zinc or Nickel plating, Alkaline blackening,Dacromet,Oil coating,

Copper plating, Sand blasting, Passivation, Polishing, and so on

|

|

Size

|

Customer Order

|

|

MOQ

|

It depends,Small order are acceptable

|

|

Packing

|

Box Packing+carton+pallets

|

As a custom spring and wire bending manufacturer, we specialize in copper wire forming, using advanced technology and innovative techniques to deliver high-quality, reliable products to our clients. Whether you need custom springs for your automotive or aerospace project, or wire forms for your medical or electronics application, we have the expertise and experience to meet your needs. Contact us today to learn more about our wire forming capabilities and how we can help you achieve your goals.