Correct use of spring

Spring is widely used. In the process of use, how to use it correctly can improve the service life and service life of spring

Please avoid the following improper use

(1) if the maximum compression is exceeded, the pressure will generate and then cause damage. If the spring is used close to the length, the spring line will be gradually close. This is because the higher the fixed number of the spring, the higher the load curve will be, and the higher the near high stress will cause the spring to break. Please do not use more than 300000 cycles.

(2) for use without preloading, the spring vibrates up and down due to clearance, resulting in spring distortion. If there is preloading, the spring is relatively stable.

(3) when the spring is used horizontally, the guide pin and spring will be worn and broken.

(4) when using without spring guidance, such as under the guidance of dance spring, it is easy to cause the distortion of the spring bottom and body. The local high pressure of the twisted part is the main cause of spring fracture. Please be sure to use inner diameter guide pin or outer diameter guide and other devices.

(5) when the flatness of the assembly surface is poor, the poor parallelism of the assembly surface will cause spring distortion, local high pressure fracture, and spring distortion in the case of poor parallelism and spring fracture in case of more than 300000 reuse. Please improve the parallelism of the assembly surface under the condition of no more than 300000 reuse.

(6) if the inner diameter of the spring and the gap between the guide pin and the guide pin are too small, the collision wear of the inner diameter will be caused, and the wear part is the main cause of the spring fracture. On the contrary, if the gap is too large, the spring will be twisted and broken, the best is the inner diameter of the spring of about -1.0mm. For springs with long free length (free length / outer diameter greater than 4), please use step or guide pin to avoid collision with the guide pin when the spring body is twisted.

(7) if the clearance between the outer diameter of the spring and the countersunk hole is too small, the outer side will expand due to spring compression and rub with the countersunk hole, resulting in force concentration fracture. The better countersunk hole diameter is the outer diameter of the Spring + 1.5mm. For free long springs, please use countersunk hole shape.

(8) if the length of the guide pin and the depth of the countersunk hole are short, the guide pin is too short, which will cause the wear and fracture of the guide pin head and the spring. The ideal length of the guide pin is set to more than 1 / 2 of the spring length, and please reverse the chamfer of C3.

(9) when the square is changed or the spring is used, the spring is forced and twisted, causing the inner ring spring to be inserted into the outer ring (or the outer ring is inserted into the inner ring), resulting in fracture.

(10) when the spring is used in series, it causes the spring to bend and exceed the length of the guide pin or countersunk hole, resulting in the fracture of the same reason, and the surface fracture of the weak load due to the slight difference of the load of the spring itself.

(11) debris and foreign matter inclusion when in use, the foreign matter inclusion part will cause the effective coil to have no effect, only the compression of other parts, the actual effective coil number will become smaller, causing high stress and fracture near the surface. Do not inclusion the foreign matter in the spring.

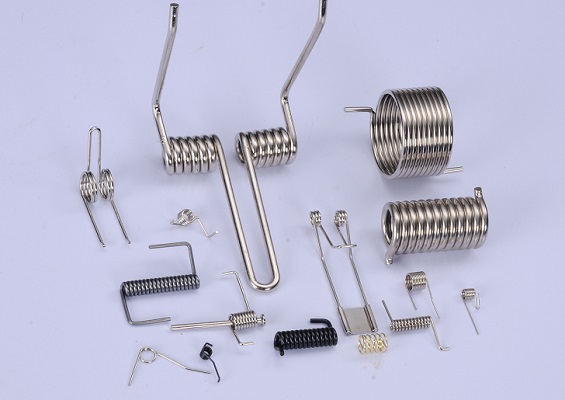

Custom springs

Follows are some details for our springs.