Extension Spring End Types: A Comprehensive Guide

As one of the most common types of springs, extension springs play a significant role in various industrial applications. They are widely used in automotive, aerospace, construction, and many other industries. Extension springs work by storing energy when they are pulled, and they release it when they are released. Therefore, extension springs must be designed and manufactured with care to ensure their safety and reliability.

As one of the most common types of springs, extension springs play a significant role in various industrial applications. They are widely used in automotive, aerospace, construction, and many other industries. Extension springs work by storing energy when they are pulled, and they release it when they are released. Therefore, extension springs must be designed and manufactured with care to ensure their safety and reliability.

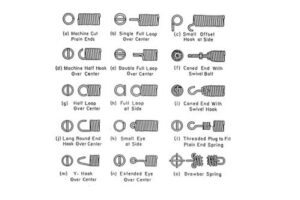

One critical aspect of extension spring design is the type of ends used. Extension springs can have different end types, each of which has its advantages and disadvantages. In this article, we will explore the most common extension spring end types and their characteristics.

1. Machine Hooks

Machine hooks are one of the most popular extension spring end types. They are easy to install and provide a secure attachment point for the spring. Machine hooks are typically used for light-duty applications where the spring is not subjected to excessive stress or tension. They are also suitable for situations where the spring needs to be easily removed or replaced.

2. Extended Hooks

Extended hooks are similar to machine hooks, but they have a longer hook section. Extended hooks are used in applications where the spring needs to be secured over a larger distance or where the spring needs to be attached to a specific point. They are also useful in situations where the spring needs to be installed in a tight space or where the spring needs to be easily removed or replaced.

3. Threaded Inserts

Threaded inserts are a popular extension spring end type for heavy-duty applications. They provide a secure attachment point for the spring and allow for easy adjustment of the spring tension. Threaded inserts are typically made of metal and are threaded to accept a bolt or screw. They are used in applications where the spring needs to be under high stress or tension, such as in automotive or aerospace applications.

4. Full Twist Loops

Full twist loops are a unique end type that provides a secure attachment point for the spring while also allowing for a small amount of lateral movement. Full twist loops are typically used in applications where the spring needs to be under high stress or tension, such as in automotive or aerospace applications. They are also useful in situations where the spring needs to be easily removed or replaced.

5. Double Loops

Double loops are another unique end type that provides a secure attachment point for the spring while also allowing for a small amount of lateral movement. Double loops are typically used in applications where the spring needs to be under high stress or tension, such as in automotive or aerospace applications. They are also useful in situations where the spring needs to be easily removed or replaced.

6. Full Hooks

Full hooks are an extension spring end type that provides a secure attachment point for the spring while also allowing for a small amount of lateral movement. Full hooks are typically used in applications where the spring needs to be under high stress or tension, such as in automotive or aerospace applications. They are also useful in situations where the spring needs to be easily removed or replaced.

Conclusion of Extension Spring End Types

In conclusion, the choice of extension spring end type depends on the specific requirements of the application. By understanding the characteristics of each end type, designers and engineers can select the most suitable option for their needs. Whether it’s machine hooks, extended hooks, threaded inserts, full twist loops, double loops, or full hooks, each end type has its advantages and disadvantages. Therefore, it’s essential to carefully consider the application’s requirements before selecting the end type.