Impact test of spring

The springs used in the buffers of some construction machinery, transport vehicles and the recoilers of guns often bear impact loads in their working process. The deformation speed of the spring bearing the impact load is very fast. For example, the deformation speed of the repeater spring of some high-speed guns can be as high as 20m / s. Under this high-speed deformation, the deformation and stress distribution of the spring are very uneven, especially when the deformation speed of the spring is higher than the allowable transmission speed of the stress in the spring, resulting in stress concentration, permanent deformation of the spring, and even fracture. Therefore, impact test shall be conducted for these springs.

On the one hand, the impact test of spring is to test the performance of spring bearing impact load. On the other hand, it can also stabilize the size of spring, improve the bearing capacity of spring and eliminate defective products. Usually, a batch of springs are sampled and tested, and all important ones can be inspected.

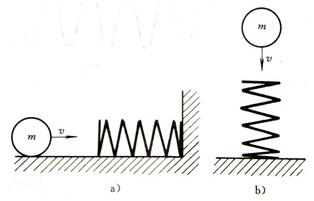

a.Horizontal;b.Vertical

The impact test can take two forms (Fig. 1), one is the impact in the horizontal direction (Fig. 1-A) and the other is the impact in the vertical direction (Fig. 1-B). The horizontal impact test can be carried out on the pendulum impact testing machine, and the vertical impact test can be carried out on the drop weight testing machine.

For the spring requiring impact test on the impact testing machine, the height and mass of the drop hammer and the number of impacts at each end of the spring shall be specified on the drawing. If the energy of the falling hammer is greater than the energy absorbed by the spring, a limit device must be installed to prevent the spring from being damaged.

After the impact test, check the free height sinking of the Compression spring, which generally shall not exceed 3% of the free height before the drop weight test. After the drop weight test, no other treatment shall be carried out.