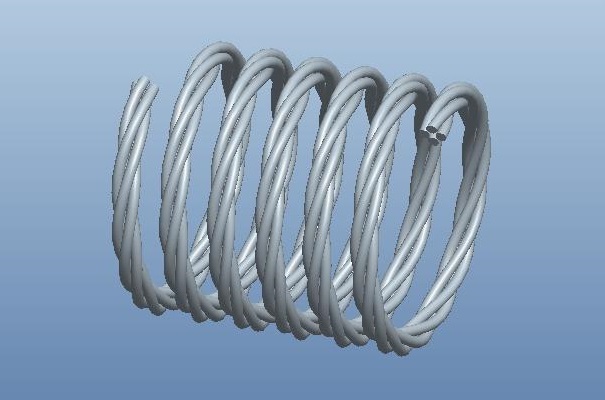

Process characteristics of multi strand spring

Due to the limitation of product structure, multi strand spring generally has the characteristics of high strength and good performance. The material is required to guarantee the final performance in terms of strength and toughness. Therefore, its material usually adopts elastic modulus E = 206 × 103n / mm2 carbon spring steel wire (gb4357) or carbon spring steel wire (gb4360). The specific specification of steel wire shall be determined according to the structural characteristics and load requirements of the product.

According to the different number of steel wire strands, multi strand springs can be divided into three strands and four strands, of which three strands are common.

There are two methods for winding multi strand springs: one is to twist the steel rope and wind the spring at the same time; The other is to screw the steel rope and wind the spring step by step, that is, screw the steel rope first, and then wind the spring. The steel rope can be screwed and wound on the lathe respectively, or it can be wound on the machine tool with automatic steel rope screwing mechanism at the same time.

The typical process can be referred to as follows:

Loading → (unscrewing the steel rope) → winding → cutting off → grinding head → appearance inspection → surface treatment (depending on the product requirements and whether the welding head is welded) → welding two ends (as required) → filing the welding head (as required) → merging the end ring (merging) → correction → heat treatment → tightening → correction → trimming the end ring (as required) → inspection → surface treatment (this process is not available for those who have undergone surface treatment) → oil immersion

Typical process parameters can be calculated according to the following formula:

1. Calculation formula for expanded length of steel wire:

L1=(πDn1m)/(cos α cos β)

D ——— pitch diameter of spring (mm)

N1 ——— total number of turns

α——— Spiral rise angle (°)

M ——- number of spring strands

β——- Cable tightening angle (°)

2. Stiffness calculation formula:

P’=(Gd4mi)/(8D3n)

G ——- shear modulus (n / mm2), generally 79 × 103~85 × one hundred and three

D ——— diameter of steel wire (mm)

I ———– cable twisting coefficient, when m = 3, β At 15 ° ~ 25 °, take 1.05 ~ 1.2; When m = 4, β At 20 ° ~ 30 °, take 1.1 ~ 1.3.

N ———– number of effective turns

During processing, the following points shall be noted:

1. Springs without support rings and springs with too thin steel wire diameter shall not be welded with spring heads, but the end steel cables shall not be obviously loose and shall be deburred. For the multi strand spring with welded head, the length of the welded part shall be less than 3 times of the cable diameter (the longest shall not be more than 10mm). The heating length shall be less than one circle, and shall be polished smoothly after welding. During gas welding, the welded parts shall be subject to local low-temperature annealing.

2. The support ring can be cold combined and hot combined according to the product requirements. It is not allowed to heat the spring to spark or whiten by heating, and the temperature of silicon manganese steel shall not be higher than 850 ℃. The bearing ring shall be in effective contact with the effective ring, and the gap shall not exceed 10% of the nominal gap between the rings.

3. The characteristics of multi strand spring can be determined by adjusting the lead, and the cable distance can be adjusted when winding. The screw pitch can be 3 ~ 14 times the steel wire diameter, but generally 8 ~ 13 times is preferred. The spring force is also closely related to the free height, parallel end ring, outer diameter and steel wire performance, which can be changed by adjusting one or more of them.

4. The tightening time of important springs is 24 hours, while that of ordinary springs is 6 hours or continuously compressed for 3 ~ 5 times, holding for 3 ~ 5 seconds each time. When pressing, the clearance between the spring and the mandrel should be 10% of the mandrel diameter. If the clearance is too small, it is difficult to operate, and if the clearance is too large, it is easy to bend and deform the spring. If one of the springs is broken during tightening, the rest shall be reprocessed.

5. For the multi strand spring with large H0 / D2 value, pay attention to its deformation during heat treatment, consider whether to wear the mandrel, pay attention to the placement mode, and select appropriate heat treatment equipment. Under the condition that repair can be carried out, multiple tempering and hot pressing can be carried out to achieve the purpose.

6. Generally, the spring surface can be treated with phosphating or other treatments. Where the coating is zinc and cadmium, hydrogen removal treatment shall be carried out after electroplating. After hydrogen removal, 3% (not less than 3 pieces) shall be sampled for retest and standing treatment, and there shall be no fracture during retest. The surface dirt, salt mark and oxide scale of the spring shall be removed by sand blowing or gasoline cleaning, but pickling shall not be used.