Understanding the Function and Importance of Torsion Springs

Torsion springs are crucial mechanical components utilized in various industries and applications. Their unique design allows them to store and release rotational energy, making them invaluable in numerous mechanisms. In this article, we will delve into the function and significance of torsion springs, exploring their mechanics and highlighting their importance in different fields.

1. Mechanism and Operation:

Torsion springs are helical springs that exert a rotational force or torque when twisted. They are typically made from high-quality materials such as steel or other alloys, which provide the necessary strength and resilience to withstand repeated twisting cycles. This design enables torsion springs to store mechanical energy when twisted and release it when the applied force is removed or reduced.

2. Energy Storage and Release:

The primary function of torsion springs is to store and release mechanical energy in rotational form. When torque is applied to a torsion spring, it undergoes deformation, twisting around its axis. This causes the spring to store potential energy within its coils. As the applied force is removed or reduced, the torsion spring returns to its original shape, releasing the stored energy in the form of rotational force.

3. Precise Force and Torque Generation:

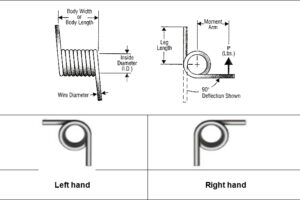

Torsion springs are designed to provide accurate and controlled levels of torque and rotational force. By varying the dimensions and properties of the spring, such as the wire diameter, coil diameter, and the number of coils, manufacturers can precisely tailor the spring’s characteristics to meet specific force requirements. This allows for precise and consistent torque generation in various applications.

4. Load-Bearing and Counterbalancing:

One of the key functions of torsion springs is to bear and counterbalance loads within a mechanism. By exerting an opposing torque, torsion springs can balance the forces exerted by other components or loads, ensuring stability and proper functioning. This load-bearing capability is especially essential in applications such as garage doors, where torsion springs counterbalance the weight of the door, making it easier to open and close.

5. Vibration Dampening and Absorption:

Torsion springs also play a vital role in vibration dampening and absorption. In applications where oscillatory motion or vibrations may occur, such as engines, machinery, or even musical instruments, torsion springs help absorb and dissipate these vibrations. By acting as a shock absorber, torsion springs minimize the transmission of vibrations, reducing wear and tear on the overall system.

6. Safety and Control:

Torsion springs contribute to the overall safety and control of various mechanisms. In applications such as clutches, brakes, and suspension systems, torsion springs provide controlled resistance and precise movement. These springs ensure smooth and controlled actions, preventing sudden or uncontrolled movements that could compromise safety.

Torsion spring function Conclusion:

Torsion springs are indispensable components that operate on the principle of rotational energy storage and release. Their ability to generate precise torque, bear loads, dampen vibrations, and provide safety and control makes them essential in numerous industries. From automotive and manufacturing machinery to aerospace, medical devices, and beyond, torsion springs play a critical role in ensuring reliable and efficient operation. The ongoing advancements in materials and design continue to expand the capabilities and applications of torsion springs, further solidifying their significance in modern engineering and technology.