Harnessing the Power of Torsion Spring Torque: A Comprehensive Guide

Torsion springs are highly versatile mechanical components widely used in various applications, from industrial machinery to everyday devices. Understanding the concept of torsion spring torque is crucial for engineers, technicians, and enthusiasts alike. In this comprehensive guide, we will delve into the intricacies of this spring torque, exploring its significance, calculation methods, and applications.

1. What is Torsion Spring Torque?

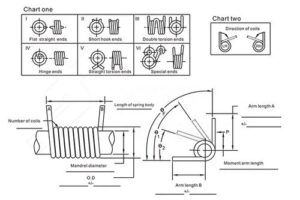

It refers to the rotational force or moment generated by a torsion spring when it is twisted or wound. This torque is a result of the spring’s material properties as well as its design, including the wire diameter, coil diameter, and number of active coils. By utilizing the torque generated by torsion springs, engineers can enable various mechanical functions and applications.

2. Calculating Torsion Spring Torque:

Calculating torsion spring torque involves understanding the spring’s physical characteristics and employing mathematical formulas. The fundamental equation for it is:

Torque (T) = K × θ

Where:

– T is the spring torque in units of force multiplied by distance (e.g., N·m or lb·in)

– K is the spring constant, also known as the torsional modulus or spring rate

– θ is the angular deflection or twist angle of the spring in radians

The spring constant (K) can be determined by dividing the spring’s spring rate (k) by the spring’s effective length (L).

3. Factors Affecting :

Several factors influence the torque generated by a torsion spring, including:

– Wire diameter: Thicker wire diameters generally result in higher torque capacities.

– Coil diameter: Smaller coil diameters increase the torque generated by the spring.

– Number of active coils: More active coils enhance the spring’s ability to generate torque.

By manipulating these factors during the design and manufacturing process, engineers can tailor the springs to meet specific torque requirements for different applications.

4. Applications :

Torsion spring torque finds applications across various industries, including:

– Automotive: They are used in automotive suspensions, clutch mechanisms, and throttle systems.

– Aerospace: They play a critical role in airplane flaps, landing gear systems, and control surfaces.

– Industrial equipment: They are employed in valves, door hinges, and garage doors, enabling smooth and controlled movement.

– Consumer electronics: Devices such as clocks, watches, and so on.

5. Achieving Optimal Torsion Spring Torque:

To maximize the performance of torque, it is essential to consider the following aspects:

– Material selection: Choosing the right material, such as high-quality steel alloys, ensures optimum torque generation and durability.

– Precision manufacturing: Accurate fabrication techniques ensure consistent torque performance across a batch of springs.

– Spring design: Customizing the spring’s physical dimensions allows for precise torque control and desired characteristics.

Conclusion:

Understanding the concept of torsion spring torque empowers engineers and designers to harness the full potential of these remarkable mechanical components. From calculating torque values to considering the factors influencing torque generation, a deep comprehension of it enables the development of efficient and reliable systems in countless applications. By applying this knowledge, engineers can unlock new possibilities, ensuring optimal performance and customer satisfaction in diverse industries.