6.4 Manufacturing accuracy and limit deviation of cold rolled cylindrical spiral torsion spring

Table 12-2-35

| Project | Spring manufacturing accuracy and limit deviation | |||

| Limit deviation of torque △T/N*mm | ±(Calculate torsion angle×β1×β2)×T’ | |||

| Accuracy Level | 1 | 2 | 3 | |

| β1 | 0.03 | 0.05 | 0.08 | |

| Coil | >3~10 | >10~20 | >20~30 | |

| β2/(°) | 10 | 15 | 20 | |

| Spring outer diameter D2 Limit deviation △D2/mm | Winding ratio C | ≥4~8 | >8~15 | >15~22 | |

| Accuracy Level | 1 | ±0.01D Min ±0.15 |

±0.015D Min ±0.2 |

±0.02D Min ±0.4 |

|

| 2 | ±0.015D Min ±0.2 |

±0.02D Min ±0.3 |

±0.03D Min ±0.6 |

||

| 3 | ±0.025D Min ±0.4 |

±0.03D Min ±0.5 |

±0.04D Min ±0.8 |

||

| Limit deviation of free angle/(°) | Coils | ≤3 | >3~10 | >10~20 | >20~30 | |

| Accuracy Level | 1 | ±8 | ±10 | ±15 | ±20 | |

| 2 | ±10 | ±15 | ±20 | ±30 | ||

| 3 | ±15 | ±20 | ±30 | ±40 | ||

| Spring outer diameter H0 Limit deviation /mm | Winding ratio C | ≥4~8 | >8~15 | >15~22 | |

| Accuracy Level | 1 | ±0.015H0 Min ±0.3 |

±0.02H0 Min ±0.4 |

±0.03H0 Min ±0.6 |

|

| 2 | ±0.03H0 Min ±0.6 |

±0.04H0 Min ±0.8 |

±0.06H0 Min ±1.2 |

||

| 3 | ±0.05H0 Min ±1 |

±0.07H0 Min ±1.4 |

±0.09H0 Min ±1.8 |

||

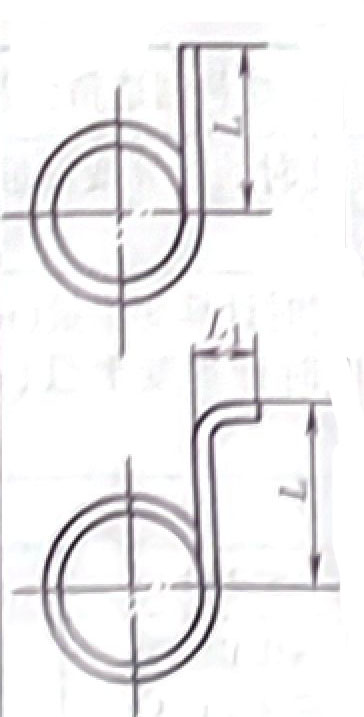

| Torsion arm length Limit deviation /mm | Material diameter d | ≥0.5~1 | >1~2 | >2~4 | >4 | ||

|

Accuracy Level | 1 | ±0.02L(L1) Min ±0.5 |

±0.02L(L1) Min ±0.7 |

±0.02L(L1) Min ±1.0 |

±0.02L(L1) Min ±1.5 |

|

| 2 | ±0.03L(L1) Min ±0.7 |

±0.03L(L1) Min ±1.0 |

±0.03L(L1) Min ±1.5 |

±0.03L(L1) Min ±2.0 |

|||

| 3 | ±0.04L(L1) Min ±1.5 |

±0.04L(L1) Min ±2.0 |

±0.04L(L1) Min ±3.0 |

±0.04L(L1) Min ±4.0 |

|||

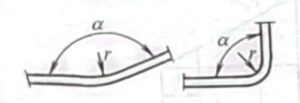

| The limit deviation of the bending angle α of the torsion arm/(°) | Accuracy Level | 1 | 2 | 3 |

|

±5 | ±10 | ±15 |

Note:

1. The manufacturing accuracy and limit deviation of spiral springs are applicable to wire cross-sectional diameter ≥ 0.5mm

2. The limit deviation of spring load, spring stiffness, and spring size is allowed to be used asymmetrically, but its tolerance remains unchanged.

3. The limit deviation of the total number of turns is used as a reference value. When there is a requirement for the hook and loop position, the hook and loop position should be ensured.

4. The free length of the extension spring refers to the length between the inner sides of its two shackles.

5. After compressing the spring with the maximum allowable load three times, its permanent deformation shall not exceed 3% of the free height

6. When a compression spring with equal pitch is compressed to 80% of the total deformation, its coils must not come into contact.