Carbon Steel Die Springs

Die Springs are specially made according to the characteristics of the mold. Through strict quality management, the springs are tested for high stress, high-speed stamping, and heat resistance. The specifications are divided into seven categories: yellow, blue, red, green, brown, purple, and silver. Customers can choose from them according to different strengths. Die springs include SWOSC-VA alloy steel, 50CRVA and MICKEY nitrogen springs, which are suitable for different levels of customer requirements. The case we shown here are customized Carbon Steel Die Springs for oversea customers.

What is Die Spring?

Mold springs come in different colors, representing the load level of the spring, reflecting the compression amount and elasticity of the compression spring. The commonly used mold spring colors are blue, red, green, and brown.

1.Selection of Carbon Steel Die Springs:

1.1 The selection of spring length ensures that the pre compression value of the spring is 2-4mm in the open mold state, and less than or equal to the large compression value when the spring is compressed in the closed mold state.

1.2. Brown springs are used for punching and forming molds.

1.3. Red springs are used for the outer release plate of the composite mold, and brown springs are used for the inner release plate.

1.4. General selection of activity positioning pins Φ 8.0 Top material pin, equipped with Φ 10.0* Φ 1.0 circular wire spring and M12.0 * 1.5 stop screw.

1.5. Spring specifications are preferred Φ 30.0 Other specifications should be considered for smaller areas.

2.Distribution of Carbon Steel Die Springs:

2.1. When arranging the spring distribution, ensure that the distance from the center of the spring through hole to the edge of the template is greater than the outer diameter D, and maintain a solid wall thickness of over 5mm from other through holes.

2.2. The arrangement of springs should consider the stress parts, and then consider the balanced and stable stress of the entire mold. The stressed part refers to the shape of the inner stripper plate of the composite mold and the surrounding area of the punch, the bending edge of the forming die around the punch of the punching die, and the area where there is tooth extraction forming.

2.3. The springs should also be evenly distributed around the inner guide pillar to ensure normal mold movement.

Carbon Steel Die Springs Factory

| Item |

Carbon Steel Die Springs Factory in China

|

|

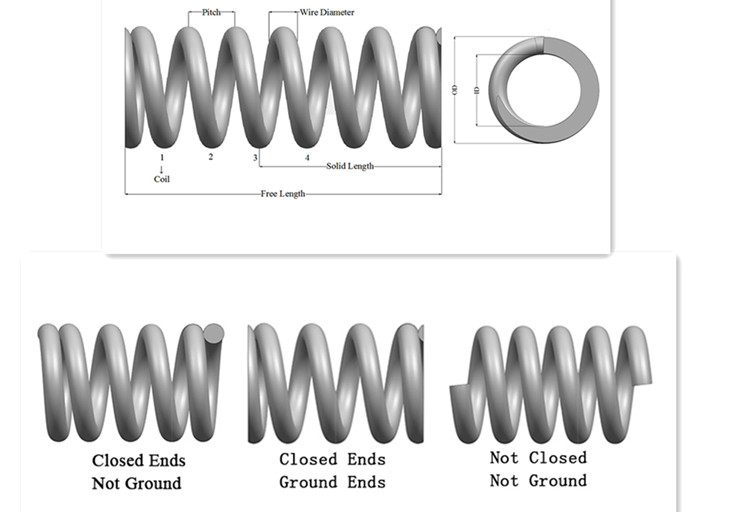

Wire Diameter

|

0.1-20mm

|

|

I.D

|

>=0.1 mm

|

|

O.D

|

>=0.5 mm

|

|

Free length

|

>=0.5 mm

|

|

Total Coils

|

>=3

|

|

Active coils

|

>=1

|

|

Material

|

SS302(AISI302)/ SS304(AISI304)/ SS316(AISI316)/SS301(AISI301)

|

|

SS631/65Mn(AISI1066)/60Si2Mn(HD2600)/55CrSiA(HD1550)/carbon steel

|

|

|

Music wire/C17200/C64200, Etc

|

|

|

Carbon Steel Die Springs Finish

|

Zinc plating, Nickel plating, Anodic oxidation,Black oxided,Electrophoresis

|

|

Power coating, Gold plating, Silver plating, Tin plating, Paint,Chorme, Phosphate

|

|

|

Dacromet,Oil coating, Copper plating, Sand blasting, Passivation, Polishing,Etc

|

|

|

Sample

|

3-7days

|

|

Delivery

|

7-15days

|

|

Warranty period

|

One year

|

|

Payment Terms

|

T/T,D/A,D/P,L/C,MoneyGram,Paypal payments.

|

|

Package

|

1.PE bag inside, carton outside/Pallet.

|

|

2.Other packages: Wooden box, individual packaging, tray packaging,tape & reel packaging etc.

|

|

|

3.Per our customer’s need.

|