The Art of CNC Wire Forming: Precision and Creativity in Manufacturing

CNC wire forming is a manufacturing process that involves the use of computer-controlled machines to bend and shape metal wires into various forms and shapes. This technology has revolutionized the manufacturing industry, allowing for the production of complex and intricate wire forms with high precision and accuracy. In this post, we will explore the art of it, its applications, and the benefits it offers to manufacturers.

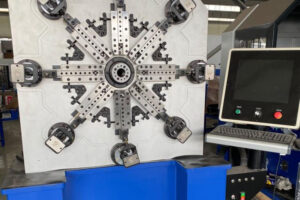

1. The Basics of CNC Wire Forming

It involves the use of specialized machines that are programmed to bend and shape metal wires according to specific designs and specifications. These machines use computer-aided design (CAD) software to create 3D models of the wire forms, which are then translated into machine code that controls the movement of the wire bending tools. The machines can bend wires of various diameters and materials, including steel,Piano wire, aluminum, and copper, with high precision and accuracy.

2. Applications

CNC Wire Forming has a wide range of applications in various industries, including automotive, aerospace, medical, and electronics. Some of the common wire forms produced using this technology include springs, clips, hooks, brackets, and wire mesh. These wire forms are used in various products, such as car seats, medical devices, electronic components, and industrial machinery.

3. Benefits

CNC wire forming offers several benefits to manufacturers, including:

– High precision and accuracy: CNC wire bending machines can produce wire forms with high precision and accuracy, ensuring that the final product meets the required specifications.

– Cost-effective: It is a cost-effective manufacturing process, as it reduces the need for manual labor and minimizes material waste.

– Versatility: Wire forming machines can produce wire forms of various shapes and sizes, allowing manufacturers to create custom designs and prototypes.

– Speed: Wire forming machines can produce wire forms at a faster rate than traditional manufacturing methods, reducing lead times and increasing production efficiency.

4. Creativity

While CNC wire forming is a highly precise and technical process, it also offers opportunities for creativity and innovation. Manufacturers can use the technology to create unique and intricate wire forms that are not possible using traditional manufacturing methods. The ability to create custom designs and prototypes also allows for greater flexibility and experimentation in product development.

Conclusion:

CNC wire forming is a highly advanced manufacturing process that offers precision, versatility, and creativity in the production of wire forms. Its applications are vast and varied, and it offers several benefits to manufacturers, including cost-effectiveness, speed, and accuracy. As technology continues to evolve, we can expect to see even more innovative uses of it in the future.