4. Cylindrical helical tension spring

The calculation of tension, deformation and strength of tension spring is basically the same as that of compression spring, except that the directions of force, deformation and stress are opposite. Therefore, the basic calculation formula of compression spring can also be applied to tension spring.

The internal force formed by the closed coil spiral tension spring during cold rolling is the force that needs to be added when the spring starts to produce tensile deformation, and is the initial tension of the tension spring. The initial tension is directly related to the type, performance, diameter of the material, the winding ratio of the spring, the form and length of the earrings, and the processing method of the spring. The tension ring spring formed by cold drawing and strengthened steel wire and cold rolling has a certain initial tension. Compared with the spring made of stainless spring steel wire and carbon spring steel wire, the initial tension is about 12% less; The higher the temperature of spring stress relieving tempering treatment, the smaller the initial tension; The tension spring that needs to be heat treated and quenched to make the spring has no initial tension.

Initial tension P0=τ0πD3/8D

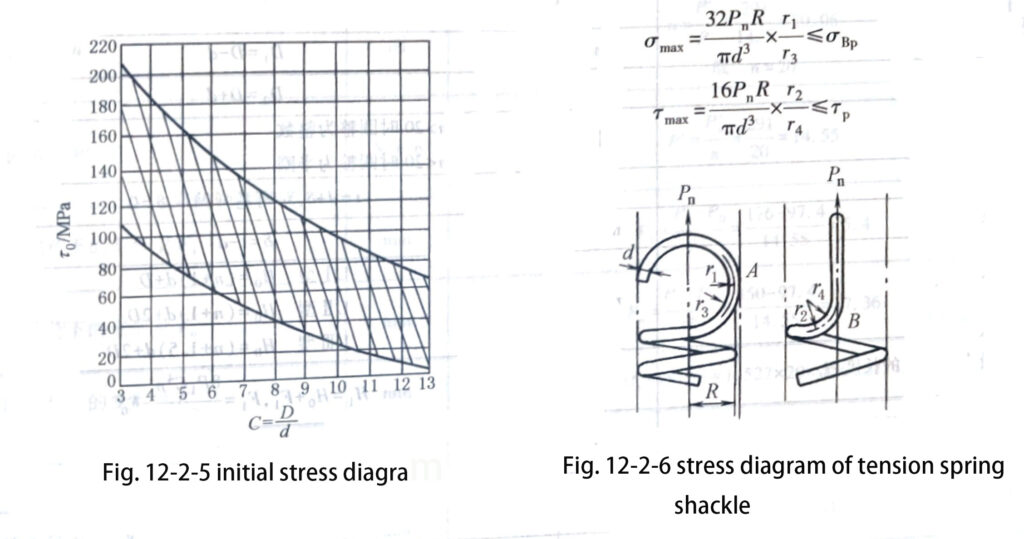

Where, τ0 is the initial shear stress of the tension spring. The initial shear stress is a value related to the winding ratio of the spring, which can be found in Fig. 12-2-5

When the tension spring is stretched, the hook and loop bear the maximum bending stress and initial stress at a and B (Fig. 12-2-6). For important tension springs, the stress can be calculated according to the following formula: