Introduction to Automobile Spring

Coil spring

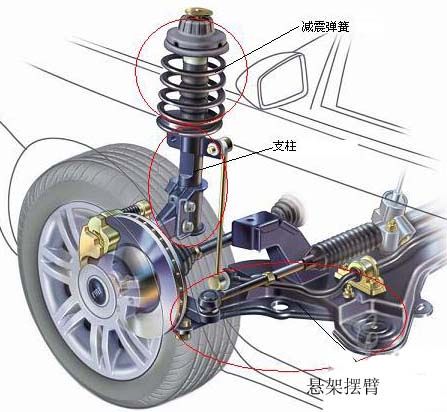

it is the most used spring in modern cars. It has strong shock absorption ability and good ride comfort; The disadvantage is that the length is large, the occupied space is large, and the contact surface of the installation position is also large, which makes the layout of the suspension system difficult to be very compact. Because the coil spring itself can not bear the lateral force, the complex combination mechanism such as four-bar coil spring has to be used in the independent suspension.

In consideration of ride comfort, we hope that the spring can be a little softer for the ground impact with high frequency and small amplitude, and when the impact force is large, it can show greater rigidity and reduce the impact stroke. Therefore, the spring needs to have two or more stiffness at the same time. Springs with different wire diameters or different pitch can be used, and their stiffness increases with the increase of load.

Leaf spring

it is mainly used for van and truck. It is composed of several slender spring sheets with different lengths. Compared with the coil spring, the utility model has the advantages of simple structure and low cost, can be compactly assembled at the bottom of the vehicle body, and friction is generated between the plates during operation, so it has attenuation effect. However, if there is serious dry friction, it will affect the ability to absorb impact. Modern cars that attach importance to ride comfort are rarely used.

Torsion bar spring

it is a long bar made of spring steel with torsion rigidity. One end is fixed to the vehicle body and one end is connected to the upper arm of the suspension. When the wheel moves up and down, the torsion bar is twisted and deformed to act as a spring.

Gas spring

use the compressibility of gas to replace metal spring. Its biggest advantage is that it has variable stiffness, which gradually increases with the continuous compression of gas, and this increase is a continuous gradual process, unlike the graded change of metal spring. Another advantage is that it is adjustable, that is, the stiffness of the spring and the height of the vehicle body can be actively adjusted.

Through the combined use of the main and auxiliary air chambers, the spring can be in the working state of two stiffness: when the main and auxiliary air chambers are used at the same time, the gas capacity becomes larger and the stiffness becomes smaller; on the contrary (only the main air chamber is used), the stiffness becomes larger. The stiffness of gas spring is controlled by computer and adjusted according to the required stiffness under the conditions of high speed, low speed, braking, acceleration and turning. The gas spring also has weaknesses. The vehicle height is controlled by pressure change. It must be equipped with an air pump, as well as various control accessories, such as air dryer. If it is not maintained properly, it will cause rust and failure in the system. In addition, if metal springs are not used at the same time, the car will not be able to run in case of air leakage.

Although the spring can reduce the impact of the road on the body, if we don’t stop its vibration as soon as possible, we will ride a jumping car. Therefore, in the process of spring movement, a certain resistance (scientific name is damping) should be added to make the vibration of the spring decay rapidly. The shock absorber is this damping device.