Precision Wire Forms Manufacturer in China

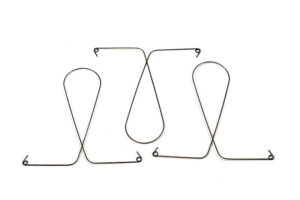

Precision wire forms are intricate components crafted from wire material sections, meticulously shaped into complex designs. Our custom wire forming services mirror the process of manufacturing miniature/micro springs, except that springs typically exhibit a coil, spiral, or helix design, whereas wire forms can assume a diverse range of unique shapes and configurations.

Custom wire forms are commonly crafted from ultra-thin wire materials ranging from approximately 0.002” to 0.240” in diameter. Various materials may be utilized, including exotic metals for specialized applications such as orthodontic wire forms and aerospace components. Nevertheless, stainless steel, carbon steel, or other high-strength alloys are frequently employed in most applications.

At China Custom Spring, our task involves shaping the optimal metal into precise forms while upholding strict tolerances through diverse CNC forming techniques like bending, coiling, and machining.

Material Selection and Design/Engineering for Wire Forms:

The custom wire forming process commences with selecting the appropriate wire material for the specific application. Material selection for aerospace components may differ significantly from that of medical devices. Choosing the right material is pivotal as it defines the wire form’s mechanical properties, functionality, durability, and resistance to environmental factors.

Following material selection, we intricately design custom wire forms using computer-aided design (CAD) software to ensure the accuracy and repeatability of the final products. Detailed models of the desired forms are created for consistent reproduction through CNC forming. Backed by decades of industry expertise, our design process considers dimensional requirements, tolerances, load-bearing capacities, long-term durability, and other functional performance aspects.

Wire Forming Processes and Techniques:

• Bending – Though seemingly straightforward, bending becomes considerably complex due to small components with precision tolerances. CNC bending machines can precisely create and replicate the delicate bends required.

• Coiling – Wire form coiling entails winding the wire material around a tiny mandrel or cylinder to form springs, helical shapes, or other intricate designs.

• Machining – Occasionally, our precision wire forms undergo secondary CNC machining processes like cutting, drilling, or grinding to achieve specific part features or dimensions.

Custom Wire Forming Services:

China Custom Spring have the capability to produce a full range of wire forms manufactured from a variety of wire types ranging from .002” up to .240” diameter in full hard materials and up to .500” from low carbon and annealed materials.

We commonly manufacture miniature and micro wire forms, hairpin clips, rings and ligation rings and more. Through design modification and optimization, we may be able to save you money. Our engineering team considers all aspects of your project including manufacturing, metallurgy, and end product functionality in order to develop the most efficient production plan possible.

Common Products and Applications for Precision Wire Forms:

- Medical Devices– Wire forms are featured in a wide range of medical equipment and healthcare devices including surgical instruments, catheters, orthopedic implants, and orthodontic products.

- Automotive– Wire forms are critical to the functionality of many complex automotive systems like seat belt mechanisms, airbag deployment systems, and electronic fuel injection systems.

- Electronics– Precision wire forms are commonly installed in electronics connectors, switches, and sensors ranging from everyday products and consumer devices to specialized medical tools and industrial equipment.

- Aerospace– Finally, wire forms are required in various critical aircraft components and spaceflight applications such as avionics, actuators, sensors, and aircraft control mechanisms.

Complete Custom Wire Form Design and Manufacturing Solutions

Specializing in miniature springs, micro wire products, and precision wire form manufacturing, We does it all. From design and tool building to manufacturing of the finished product, our company strives to meet or exceed your every expectation in quality and repeatability. Founded in 1984, our unparalleled experience and product flexibility will be an asset to your next custom wire form project.