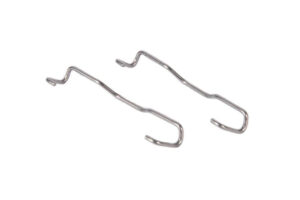

Stainless Steel Wire Bending

According to our experience in wire forming or bending, stainless steel always to be good choice. It’s good for anti-corrosion performance and tensile strength is not bad.Therefore, when our customer design new wire forms, they always ask us to make it in stainless steel, even through the material cost is a little bit higher.

According to our experience in wire forming or bending, stainless steel always to be good choice. It’s good for anti-corrosion performance and tensile strength is not bad.Therefore, when our customer design new wire forms, they always ask us to make it in stainless steel, even through the material cost is a little bit higher.

Why Stainless Steel Wire Bending is Important

Stainless steel is a popular material for wire bending due to its durability, corrosion resistance, and aesthetic appeal. Stainless steel wire products can be found in a variety of industries, from automotive to medical. These products can be used for everything from handrails and shelving to surgical instruments and dental implants.

Regardless of the project, the importance of precision and accuracy cannot be overstated. Proper wire bending ensures that your product will fit seamlessly into its intended space, and that it will function correctly for its intended purpose. In addition, quality workmanship can enhance the overall appearance and durability of the product, increasing its value and longevity.

The Importance of Finding a Professional

While there are many metal fabrication shops out there, not all of them specialize in stainless steel wire bending. In fact, many may not have the proper equipment or experience to deliver the level of precision and accuracy required for this type of work.

When searching for a professional, it’s important to do your research. Look for a shop that has a proven track record of producing high-quality wire bending products. Additionally, consider whether they have experience with the specific type of product you need. For example, if you need wire bending for a medical device, look for a shop that has experience with medical-grade stainless steel.

Finally, don’t be afraid to ask for references and examples of previous work. A reputable professional will be happy to provide you with this information, as it demonstrates their commitment to quality and customer satisfaction.

Wire Bending Ability

| Wire diameter |

0.06mm-12mm

|

|

Length/dimension

|

custom made

|

|

Process

|

|

|

Material

|

Stainless steel, brass, carbon steel, piano wire, etc.

|

|

Surface treatment

|

Zinc plating, nickel plating, anodizing, black oxide, electrophoresis, welding、Power Coating, Gold Plating, Silver Plating, Tin Plating, Paint, Chrome Dacromet, oil coating, copper plating, sandblasting, passivation, polishing, etc.

|

|

Stainless Steel Wire Bending OEM & ODM

|

Acceptable

|

|

USE

|

Zinc,Chorme,Nickel, Silver,Gold, Tin,Powder coating,Oxide black or customzied

|

|

Payment terms

|

L/C, D/P, D/A, T/T, Western Union, MoneyGram

|

|

Packing

|

PE bag, carton, wooden box, individual packaging, according to customer needs

|

Please contact us with drawing or samples of your wire bending parts. We will quote you ASAP.