Centered winding of cylindrical spiral torsion spring

Generally, there are two methods for winding the spring with a round buckle: one is continuous winding, which involves first winding a long string of spring blanks, then cutting them into individual blanks of a certain size, and then straightening the ends of the blanks to produce the twisted hips. The other method is single winding, in which the length of material required for the twisted arm at one end is left before winding, and the length of material required for the twisted arm at the other end is left after cutting after winding, and then the twisted arm is produced

The basic shape of a double-arm torsion spring is shown in Figure 34. There are many types of coiling devices, but the basic principle is similar. Before coiling, the coil material is cut and straightened after calculating the length to be coiled, and then made into a U shape. It is then coiled on a specialized coiling device.

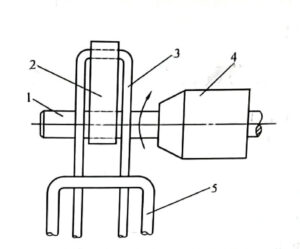

Figure 3-5 is a schematic diagram of rolling a double-arm torsion spring. Before rolling, the movable shoulder block 2 is clamped to the flat part of the spindle, the completed U-shaped business card is placed in the groove of the movable shoulder block 2, the spindle is clamped in the collet 4, and the pressure bar 5 presses against the U-shaped blank 3 to make it closely adhere to the spindle. Rotating the spindle manually or by power can complete the rolling of the double-arm torsion spring. For safety reasons, when using power transmission, the speed of the device should be lower

Figure 3-4 Double-arm spiral torsion spring

Figure 3-5, a device for winding the double-arm spiral torsion spring with a core for 1n years

1. a spindle 2. a movable shoulder block 3. a U-shaped blank 4. a collet 5. a pressure rod

The part drawings of the movable shoulder block and the spindle are shown in Figures 3-6a and 3-6b, respectively.