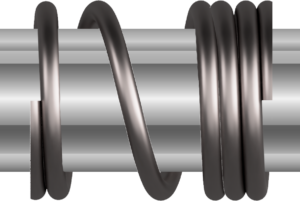

Understanding Compression Spring End Types

Compression springs are an essential component in various mechanical and engineering applications. These springs are designed to store energy when compressed and release it when the load is removed. They come in different sizes, shapes, and end types. In this article, we will focus on the different compression spring end types and their applications.

Types of Compression Spring End:

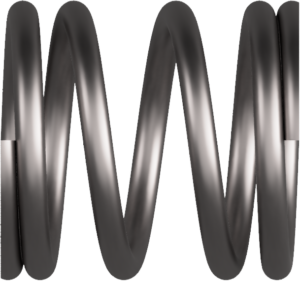

1. Open End:

Open-end springs are coils that remain unaltered after the coiling process, resulting in a naturally uneven end. This characteristic offers a distinct advantage as it allows for increased travel compared to springs with closed ends. The absence of dead coils at each end creates additional space within the solid height, enabling enhanced travel capabilities.

The utilization of open-end springs is particularly beneficial in applications where precision at the ends is not of utmost importance. This cost-effective option ensures optimal performance without compromising functionality. By leveraging open-end springs, manufacturers can strike a balance between affordability and efficiency, making it an ideal solution for a variety of industrial applications.

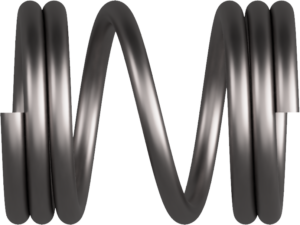

2. Closed End:

Closed ends are characterized by their squared edges and have a pitch between the coils. This type of spring end is used in applications where the spring needs to be confined within a space or housing. The closed end provides a more stable spring structure, reducing the risk of buckling or collapsing.

3.Closed and Squared Ends

This setup offers a smooth and even surface, eliminating the need for grinding. It is ideal for manufacturing precise and intricate metal components by injecting molten metal into molds. The closed and squared ends provide stability and minimize the risk of toppling when subjected to heavy loads. This configuration is specifically designed for compression springs with a slenderness ratio below 3.5, enabling them to remain upright without any external support.

4. Ground End:

Ground ends are characterized by their flattened and ground edges. This type of spring end is often used in applications where the spring needs to be seated or pressed against a flat surface. Ground ends provide a stable base for the spring to sit on, reducing the risk of slippage or deformation.

5.Closed and Ground Ends

By precision grinding the ends of the spring, we can achieve a smoother and more accurate surface, enhancing the contact with the load. This particular end type is particularly suitable for high-precision applications that demand consistent compression under load, commonly found in industries such as manufacturing and automotive. Closed and ground ends are specifically recommended for springs with a slenderness ratio exceeding 4, ensuring optimal performance.

6.Double Closed Ends

This specialized configuration involves both ends of the spring being closed, providing improved vertical stability and resistance to lateral forces without being ground. This end type proves especially beneficial in applications where the spring needs to align itself with minimal guidance. Although double ends require additional solid height, the trade-off is increased stability.

7 Squared End:

Squared ends are characterized by their flat and squared edges. This type of spring end is often used in applications where the spring needs to be mounted to a component or machine. Squared ends provide a stable base for the spring to sit on, reducing the risk of slippage or deformation.

8. Tangential End:

Tangential ends are characterized by their rounded edges and no pitch between the coils. This type of spring end is often used in applications where the spring needs to be compressed along its axis. Tangential ends provide a smooth and continuous compression, reducing the risk of buckling or collapsing.

9.Triple or more closed ends

This custom hybrid option offers numerous advantages, particularly for compression springs with fine wire diameters ranging from .005 to .025 thousandths of an inch. It is specifically designed to provide extra stability when compressing springs with a combination of fine wire diameter and large spring index.

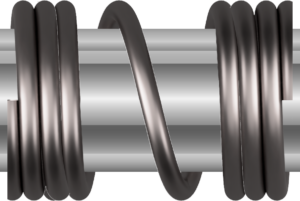

10.multiple closed ends on one side

This option allows for multiple closed ends on one side of the spring, facilitating the threading of the spring’s inner diameter over a threaded bolt or shaft. By having multiple closed ends, it becomes possible to securely assemble the spring onto the thread. It is crucial to ensure that the spring’s wire diameter matches the thread size, while the compression spring’s inner diameter aligns with the outer diameter of the bolt for a proper fit.

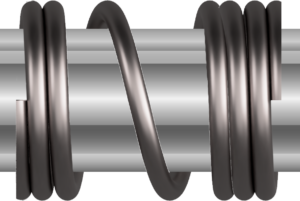

11.One Closed End and Multiple Closed Ends

This option allows for one closed end on one side of the compression spring, while the other side features multiple closed ends. This combination provides stability at the base of the spring and a closed end at the top. Additionally, this end type can be ground to achieve a highly precise flat surface, resulting in superior stability.

Applications:

The different compression spring end types have different applications based on their design and structure. Open ends are often used in applications where the spring needs to be attached or detached easily, such as in automotive engines or shock absorbers. Closed ends are often used in applications where the spring needs to be confined within a space or housing, such as in medical devices or electronic equipment. Ground ends are often used in applications where the spring needs to be seated or pressed against a flat surface, such as in industrial machinery or aerospace equipment. Squared ends are often used in applications where the spring needs to be mounted to a component or machine, such as in construction equipment or agricultural machinery. Tangential ends are often used in applications where the spring needs to be compressed along its axis, such as in aircraft landing gear or robotics.

Conclusion:

In conclusion, understanding the different compression spring end types and their applications is essential for selecting the right spring for a specific application. The open end, closed end, ground end, squared end, and tangential end all have their unique design and structure, making them suitable for different applications. By choosing the right compression spring end type, you can ensure the optimal performance and longevity of your equipment or machinery.