Custom Made Compression Spring

We offer all kinds of Custom Made Compression Spring according to sample or drawings.We trust that our price are competitive and quality is good too.Many foreign guests come to us for customized springs. In order to ensure the quality of customized springs, we must briefly introduce the technical data and requirements of compression springs here for your reference.

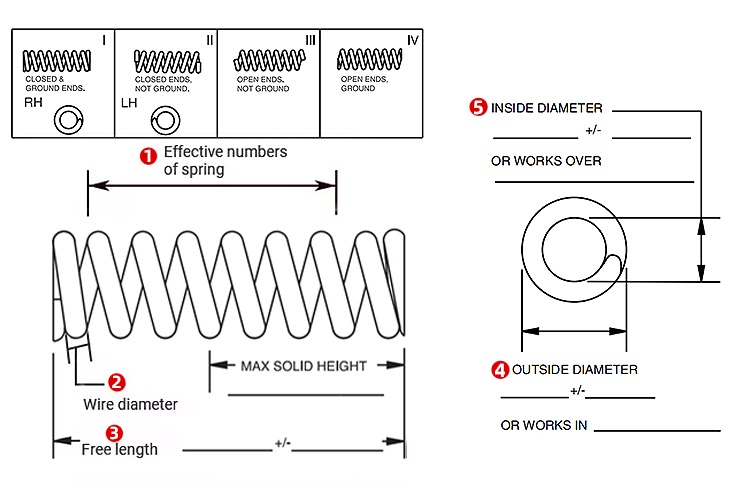

Spring Main Parameter

Units of measurement :

English (inch and pound) and metric units are used.

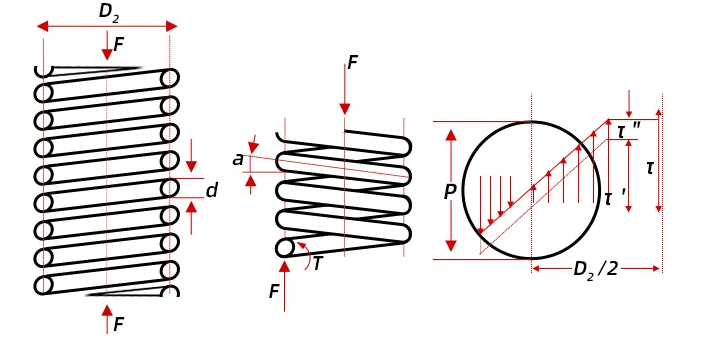

Spring Stress

The requirements and dimensions of load and deformation determine the stress of the spring. When a load is applied to a compression spring, the winding coil of the spring produces stress during the torsion process of the spring. The surface stress of steel wire is the largest; With the change of spring deformation, the load will also change, which leads to the appearance of operating stress range. The service life of the spring is restricted by the stress and stress range. The larger the stress range, the lower the maximum stress generated in order to achieve the same service life. If the stress range is small or the spring is only suitable for static load, relatively large stress can be generated. The stress when the spring is at the compression height must be sufficient to perform the predetermined shape and small enough to avoid permanent damage, because the spring is usually compressed to the compression height during installation.

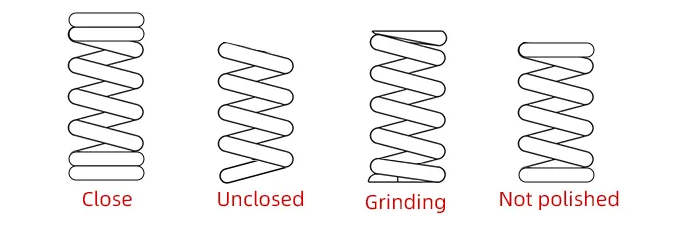

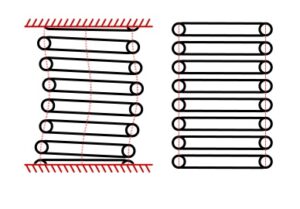

Custom Made Compression Spring Closing

There are four closing methods for the compression spring which are smooth and not smooth, closed or not closed.

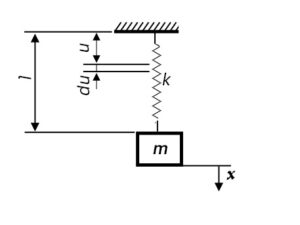

Spring Stiffness

Spring stiffness refers to the load change perunit of deformation usually expressed in pounds per inch (lbs / in),

or (N/mm)

Spring Setting

This happens when the spring load exceeds the elastic limit of the material itself. This is a permanent deformati-on. When the spring is forced, it will not return. Custo-mers can choose whether to set the spring according to their own needs.

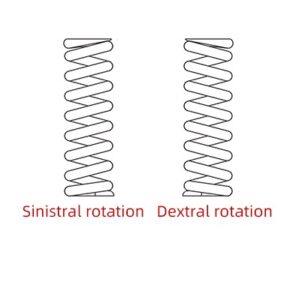

Rotation Direction

Spiral compression spring winding mode is divided into left rotation and right rotation, simila r to screw thread.

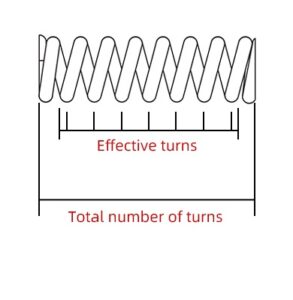

Number Of Coils

There are two main counting methods for coils which are applicable to springs effective coils and total, coils.

Working Hole Diameter

It is the reference value for, placing the compression spring into the outer hole. Genmpression spring fitting which is usually erally it is the internal diameter of the coslightly larger than the outer diameter of mistaken for the size, of the spring itself. The design of the hole diameter shall beexpansion value, of the outer diameter of the co-mpression spring, and the tolerance of the outer diameter of the spring under load shall be considered.

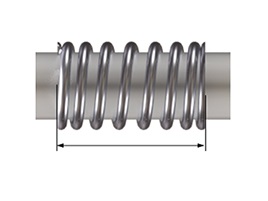

Working Rod Diameter

This is the reference value for the rod passing through the compression spring. Basically, it is a fitting part. This rod can be used as a guide shaft to prevent the tolerance of the compression spring. spring from bending or springing under load. The rod diameter shall be designed to be slightly less than the inner diameter.

Pressing Height

This is the length of the compression spring under the maximum load. In fact this when all coils are pressed together. It is the height of the compression spring.

Compression Load

This is used to measure the load when the spring is forced to make all coils comp let ey compressed together.The pres sing load can help the product designer to quickly fi nd the parameters of the ma ximum working load capacity of the spring, so as to avoid permanent deformation caus ed by overload of the spring.

Free Length

The length when the spring is not loa-ded. Note For ext ension springs, incl-ude the length inside the hook end.

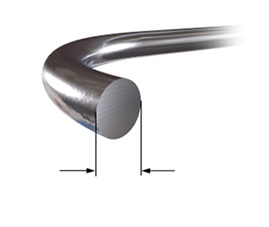

Wire Diameter

This is used to measure the size of the raw material of the spring. Traditional springs are made of round steel wire.

Outer Diameter

The diameter of the cylindrical shell formed by the outer surface of the spring coil.

Custom Made Compression Spring Material

Common types include carbon steel, stainless steel, nickel alloys, copper alloys and cobalt alloys. Your working environment can determine the material of the spring. Review materials post treatments, and plating.

Custom Made Compression Spring Treatment

Springs have many surface treatments and electroplating treatments.

Select the best surface treatment and electroplating method according to the application field of the spring. The surface treatment of the spring can protect the spring and help us identify the spring model.

Types And Shapes Of Custom Made Compression Spring

.

There are many shapes of compression springs. The customized spring can be designed into the shape you need according to the actual use environment.

Custom Made Compression Spring Manufacturing

Hourglass Spring

The two ends of hourglass spring g-radually become smaller toward the center, and the outer ring diameter is larger.

Barrel Spring

The barrel spring has a larger center diameter and both ends gradually narrows toward.

Non-circular Spring

The center of Non-circular spring is round, and it gradually narrows toward the end.