Compression Coil Springs

This Compression Coil Springs is customized by a foreign guest. The specific reference information of the product is as follows,

Material: Spring steel 72A

Finish : Black Oxid coating

COILS: 5 (1 START + 3 ACTIVE + 1 END)

ENDS: CLOSED, NOT GROUND

WINDING: RIGHT-HAND WOUND

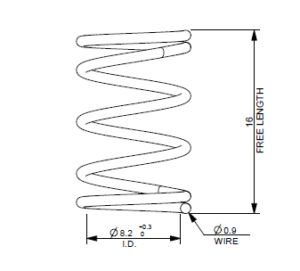

DIMENSION: AS BELOW DRAWING

Compression Coil Springs Factory

|

Product name

|

Custom made Steel Coil Springs

|

|

Type

|

|

|

Wire diameter

|

0.06mm-100mm

|

|

Length/dimension

|

|

|

Product Code

|

Customized or to be confirmed

|

|

Material

|

Stainless steel, brass, carbon steel, piano wire, etc.

|

|

Compression Coil Springs Surface treatment

|

Zinc plating, nickel plating, anodizing, black oxide, electrophoresis, welding、Power Coating, Gold Plating, Silver Plating, Tin Plating, Paint, Chrome Dacromet, oil coating, copper plating, sandblasting, passivation, polishing, etc.

|

|

OEM & ODM

|

Acceptable

|

|

MOQ

|

100pcs

|

|

Payment terms

|

L/C, D/P, D/A, T/T, Western Union, MoneyGram

|

|

Packing

|

PE bag, carton, wooden box, individual packaging, according to customer needs

|

What is Compression Spring

It is an open coil coiled or pressed coil spring.It is used to counter the axial force generated during compression. Compression spring is the most common metal spring structure. Helical compression spring is the most common metal spring configuration. These springs can work independently, although they are usually mounted on guides or in holes.When you apply a load on the spring to make it shorter it will have resistance and try to return to the original length The compression spring will resist the linear pressure (thrust). In fact, this spring is the most effective one for storing energy.

Spring Structure

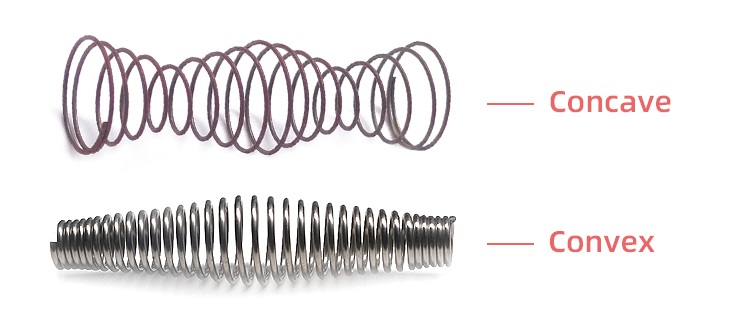

Compression Coil Springs, have the same diameter and pitch throughout their length. This structure is a standard compression spring standard part. Spring custom parts can have variable diameters or pitches, or both such as hourglass (concave),cone, and barrel (convex).

Application

From automobile engines and large presses to major electrical appliances from lawn mowers to medical equipment- mobile phones, electronic equipment and sensitive instruments and equipment. Compression Coil Springs should be installed wherever a button is needed. The tower shaped metal spring is usually used in the working environment with low bonding height and strong resistance to impact.