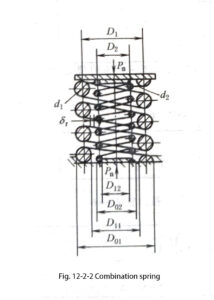

Design and calculation of combined spring

When the cylindrical helical compression spring with large load and limited installation space is designed, the combined spring can be used (Fig. 12-2-2). This kind of spring is lighter than ordinary spring, and the diameter of steel wire is smaller, so it is convenient to manufacture.

When designing the combined spring, the following matters should be paid attention to:

1) The strength of the inner and outer springs should be close to the same. After calculation, the following relationship exists

d1/d2=D1/D2=√ ̄Pn1/Pn2 and Pn=Pn1+Pn2

Generally, the ratio of Pn1 (maximum working load of outer spring) to Pn2 (maximum working load of inner spring) of combined spring is 5:2. During the design, the load of the outer and inner springs shall be distributed according to this ratio, and then the design steps of a single spring shall be followed.

2) The deformation of the inner and outer springs should be close to the same. The deformation Fn of one spring under the maximum working load should not be greater than the working limit deformation Fj of the other spring. The actual deformation difference can be adjusted with shims.

3) In order to ensure the concentric relationship of the combined spring and prevent the deflection of the inner and outer springs, the rotation directions of the two springs should be opposite, one right rotation and the other left rotation.

4) The radial clearance δr of the combined spring shall meet the following relationship.

δr=(D11-D02)/2≥(d1-d2)/2

5) The bearing surface structure at the end of the spring shall be able to prevent the internal and external springs from offsetting during operation.