How to Select the Right Compression Spring: A Comprehensive Guide

Compression springs are widely used in various industries for their ability to store energy and provide resistance to external forces. However, selecting the right compression spring for your specific application can be a daunting task. This article aims to guide you through the process of selecting the perfect compression spring by considering various factors such as material, dimensions, load requirements, and more.

1. Understand the Application to select Compression Spring:

Before diving into the technical aspects of selecting a compression spring, it is crucial to have a clear understanding of your application’s requirements. Consider the function, environment, and intended use of the spring. This will help you determine the necessary specifications and narrow down your options.

2. Identify the Load Requirements:

The load requirements of your application play a significant role in selecting the appropriate compression spring. Determine the maximum load the spring needs to withstand and the required force to achieve the desired deflection or compression. This will help you calculate the spring rate, which is the amount of force required to compress the spring by a certain distance.

3. Material Selection of Compression spring:

The material of the compression spring is crucial for its performance and durability. The most commonly used materials for compression springs include stainless steel, carbon steel, alloy steel, and music wire. Each material has different properties in terms of strength, corrosion resistance, temperature tolerance, and cost. Consider these factors to select the material that best suits your application’s needs.

4. Spring Dimensions:

The dimensions of a compression spring determine its physical characteristics such as length, inner and outer diameters, wire diameter, and number of coils. These dimensions directly impact the spring’s load-bearing capacity and deflection characteristics. Consult the spring design charts or work with a professional spring manufacturer to determine the optimal dimensions based on your load requirements and space constraints.

5. Spring Rate and Stiffness:

The spring rate and stiffness are crucial factors to consider when selecting a compression spring. The spring rate indicates how much force is required to compress the spring per unit of deflection. Higher spring rates provide greater resistance to compression, while lower rates offer more flexibility. Carefully analyze your application’s requirements and select a spring with an appropriate spring rate to achieve the desired performance.

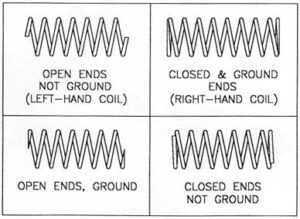

6. End Types and Finishes:

Compression springs come with various end types, such as open ends, closed ends, and various combinations of hooks or loops. The selection of the appropriate end type depends on how the spring will be mounted or connected within the application. Additionally, consider the surface finish of the spring, as it can affect its performance, corrosion resistance, and longevity.

7. Consider Other Factors:

Apart from the primary factors mentioned above, it is essential to consider other application-specific factors such as temperature variations, vibration, space limitations, and cycle life requirements. These factors can further influence the selection process and ensure the longevity and reliability of the compression spring in your application.

Conclusion:

Selecting the right compression spring requires a thorough understanding of your application’s requirements, load specifications, material properties, and dimensional considerations. By carefully analyzing these factors and working closely with a reputable spring manufacturer, you can ensure the optimal performance, longevity, and reliability of your compression spring in your specific application.

Remember, choosing the right compression spring is a critical step in achieving the desired functionality and safety for your application.