Type, performance and application of spring

There are many types of springs and many classification methods. The spring types listed in table 12-1-1 are classified according to the structural shape

Table 12-1-1 Types, properties and applications of springs

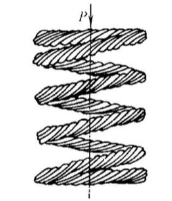

| Type | Structure diagram | Property line | Performance and Application | |

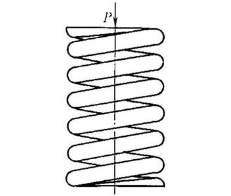

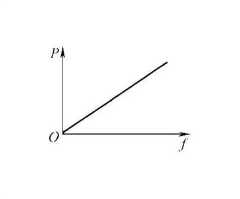

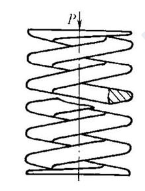

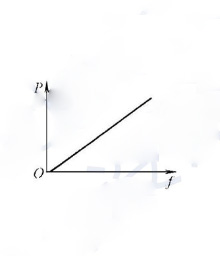

| Cylindrical coil spring | Circular section cylindrical helical compression spring |  |

|

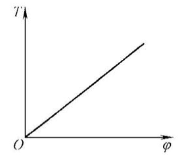

The characteristic line is linear, the stiffness is stable, the structure is simple, the manufacture is convenient, and it is widely used in mechanical equipment for cushioning, vibration reduction, energy storage and motion control |

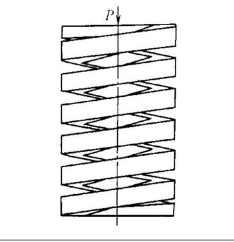

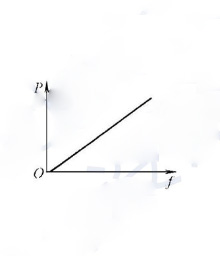

| Rectangular section cylindrical helical compression spring |  |

|

Under the same space conditions, the rectangular section cylindrical helical compression spring has greater stiffness and absorbs more energy than the circular section cylindrical helical compression spring. The characteristic line is closer to a straight line and the stiffness is closer to a constant | |

| Flat section cylindrical helical compression spring |  |

|

Compared with cylindrical helical compression spring with circular section, it has large energy storage, low compression height and large compression amount. Therefore, it is widely used in devices with small installation space, such as engine valve mechanism, clutch and automatic transmission | |

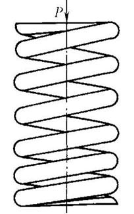

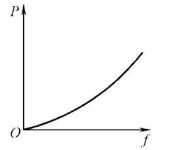

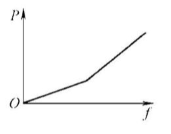

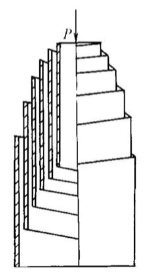

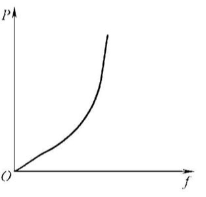

| Unequal pitch cylindrical helical compression spring |  |

|

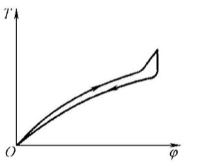

When the load increases to a certain extent, with the increase of load, the spring gradually tightens from the small pitch, the stiffness gradually increases, and the characteristic line changes from linear to increasing. Therefore, its natural frequency is variable, which can better eliminate or mitigate the influence of resonance. It is mostly used in high-speed load changing mechanisms | |

| Multi strand cylindrical coil spring |  |

|

The material is steel wire rope made of thin steel wire. When the wire rope is not loaded, the contact between the wires of the wire rope is relatively loose. When the external load reaches a certain degree, the contact becomes tight. At this time, the spring rigidity increases, so the characteristic line of the multi strand spiral spring has a break point. Compared with the ordinary cylindrical spiral spring with the same cross-section material, it has higher strength and greater damping effect. It is often used in weapons and aeroengines. | |

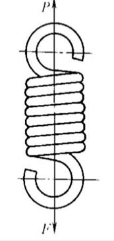

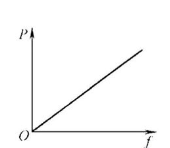

| Cylindrical helical tension spring |  |

|

The performance and characteristics are the same as those of the circular section cylindrical spiral compression spring. It is mainly used in situations subject to tensile load, such as the tension spring used in the overload safety device of the coupling and the pawl return tension spring in the ratchet mechanism | |

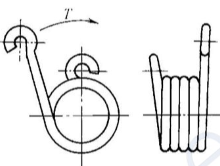

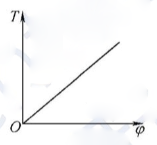

| Cylindrical helical torsion spring |  |

|

It bears torsional load and is mainly used for pressing, energy storage and elastic links in transmission system. It has linear characteristic line and is widely used, such as dynamometer and forced air valve closing mechanism | |

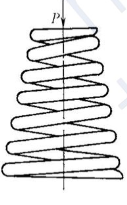

| Variable diameter coil spring | Conical coil spring |  |

|

The function is similar to that of the coil spring with unequal pitch. After the load reaches a certain degree, the spring gradually tightens from the large coil to the small coil. After the coil begins to contact, the characteristic line is nonlinear, the stiffness gradually increases, and the natural vibration frequency is a variable value, which is conducive to eliminating or mitigating resonance. The anti resonance ability is stronger than that of the compression spring with equal pitch. This kind of spring has compact structure and good stability. It is mostly used to bear large loads and reduce vibration, such as suspension spring applied to heavy vibrating screen and automobile transmission |

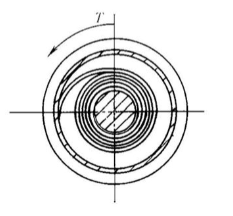

| Volute coil spring |  |

|

Compared with other springs, volute coil spring can absorb more energy in the same space, and the friction between its plates can be used to attenuate vibration. It is often used in piping systems that need to absorb thermal expansion deformation and damping vibration or components connected with piping systems, such as steam and water piping systems in thermal power plants. Its disadvantage is that the gap between plates is small, quenching is difficult, shot peening can not be carried out, and the manufacturing accuracy is not high enough. | |

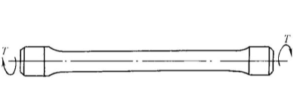

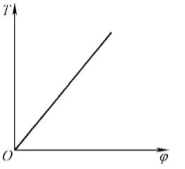

| Torsion bar spring |  |

|

The structure is simple, but the requirements for material and manufacturing accuracy are high. Mainly used as a car And suspension springs for small vehicles, auxiliary springs for valves in internal combustion engines, and auxiliary springs for air springs and regulators |

|

| Plain Belleville spring |  |

|

It has strong load-bearing buffer and vibration damping capacity. Different characteristic lines can be obtained by using different combinations. It can be used for pressure safety valve, automatic switching device, reset device, clutch, etc | |

| Ring spring |  |

|

It is widely used in occasions that need to absorb large energy but space size is limited, such as locomotive traction device spring, buffer spring of crane and cannon, damping spring of forging hammer, braking spring of aircraft, etc | |

| Plane volute spring |  |

|

Hairspring is a plane volute spring made of small-size metal belt. It can be used as measuring element (measuring hairspring) or pressing element (contacting hairspring) | |

|

|

The spring is mainly used as an energy storage element. Clockwork is reliable and easy to maintain. It is widely used in timing instruments and time control devices, such as clocks, recording instruments, household appliances, etc., and as a power source in motor toys | ||

| Leaf spring |  |

|

Leaf spring is a kind of metal sheet with rectangular cross section, which is mainly used in occasions with small load and deformation. It can be used as a sensitive element in a measuring instrument or an automatic device, as well as an electric contact point, a pawl of a ratchet mechanism, a positioner and other compression springs, a support or a guide rail | |

| Steel Leaf spring |  |

|

Factory leaf spring is composed of multiple spring steel plates. It is widely used as a suspension device in automobiles, tractors and trains for cushioning and vibration reduction. It is also used as a vibration reduction device in various mechanical products with high stiffness | |

| Rubber spring |  |

|

Because of the small elastic modulus, the rubber spring can obtain large elastic deformation, which is easy to achieve the required nonlinear characteristics. The shape is unlimited, and the stiffness in all directions can be freely selected according to the design requirements. The same rubber spring can bear multi-directional load at the same time, so the structure of the system can be simplified. The application of rubber spring in mechanical equipment is expanding day by day | |

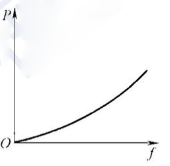

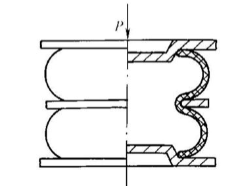

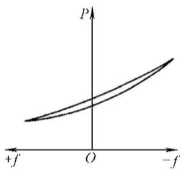

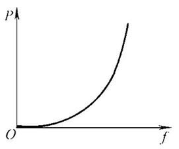

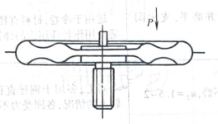

| Rubber-metal spiral composite spring |  |

|

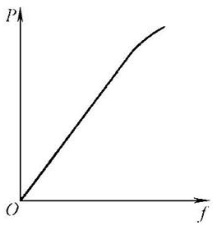

Property lines are incremental. Compared with the rubber spring, the rubber metal spiral composite spring has greater rigidity and greater damping than the metal spring. Therefore, it has the advantages of large bearing capacity, strong vibration damping and wear resistance. It is suitable for suspension structure of mining machinery and heavy vehicles. | |

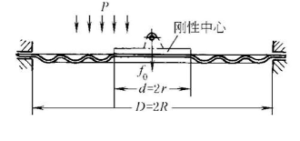

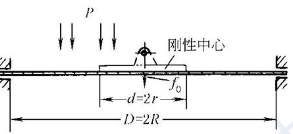

| Air spring |  |

|

Air spring is a kind of non-metallic spring that uses the compressibility of air to achieve elastic effect. It can greatly improve the dynamic performance of the vehicle when used in the vehicle suspension device, so as to significantly improve its running comfort. Therefore, air springs are widely used in cars and trains | |

| Diaphragms and capsules | Corrugated diaphragm |  |

|

It is used to measure various quantities that are non-linear with pressure, such as the flow of liquid or gas in the pipeline, the flight speed and altitude of the aircraft, etc. |

| Flat diaphragm |  |

|

It is used as the sensitive element of the instrument and can isolate two different media, such as the flexible sealing device in case of deformation due to pressure or vacuum | |

| Capsule |  |

The characteristic line varies with the number, density and depth of corrugations | To facilitate installation, two identical diaphragms are connected into a box shape along the periphery | |

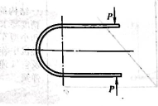

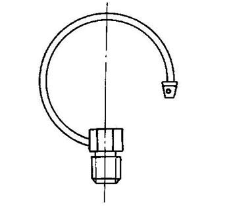

| Pressure spring tube |  |

|

Displacement is generated at the end under the pressure of fluid, and the displacement is transmitted to the pointer through the transmission mechanism, which is used for pressure gauge, thermometer, vacuum gauge, liquid level gauge, flowmeter, etc | |