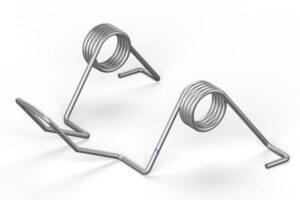

Double Twist Torsion Springs

Mechanical engineering is an ever-evolving field that has seen numerous advancements over the years. One of the most important components of mechanical engineering is the Double Twist Torsion Spring. This unsung hero of mechanical engineering has been instrumental in the success of many industrial applications. As a professional maker, we will discuss the this kind of Spring, its manufacturing process, and its advantages.

Mechanical engineering is an ever-evolving field that has seen numerous advancements over the years. One of the most important components of mechanical engineering is the Double Twist Torsion Spring. This unsung hero of mechanical engineering has been instrumental in the success of many industrial applications. As a professional maker, we will discuss the this kind of Spring, its manufacturing process, and its advantages.

What are Double Twist Torsion Springs?

They are a type of torsion spring that is designed to work in a twisting motion. They are made of hardened steel wire and are used in a variety of applications, including automotive, aerospace, and medical devices. These springs are known for their ability to store and release energy, making them an important component in many mechanical systems.

Manufacturing Process

The manufacturing process of Double Twist Torsion Springs is an intricate one. It involves a series of complex steps that need to be followed to ensure that the final product is of high quality. The process begins with the selection of high-quality materials, which are then subjected to heat treatment to increase their strength and durability.

The wire is then coiled around a mandrel in a specific pattern to create the desired shape of the spring. The coiling process is done by special machines that are capable of producing high-quality springs with consistent dimensions. The final step is to remove the spring from the mandrel and perform any necessary finishing operations, such as grinding or shot peening, to improve the surface finish of the spring.

Advantages of Double Twist Torsion Springs

They offer many advantages over other types of springs. One of the most significant advantages is their ability to store and release energy in a controlled manner. This makes them ideal for use in applications that require precise control over the movement of mechanical parts.

Another advantage of Double Twist Torsion Springs is their durability. They are made of high-quality materials that are designed to withstand the rigors of industrial applications. This means that they can last for a long time without needing to be replaced, reducing maintenance costs and downtime.

Torsion Spring Manufacturer

|

Material

|

Carbon steel(SWC), Alloy steel, SEA9260/ 9254/ 6150/ SUP9/ SUP10/ SUP12 /, 51CrV4, stainless steel, music wire/piano wire(SWP);beryllium copper etc.

|

|

Wire diameter

|

0.2~85mm

|

|

Double Twist Spring Finish

|

Zinc, Chorme, Nickel, Silver, Gold, Tin, Powder coating, Oxide black or customized

|

|

Testing equipment

|

CMM;Tool microscope;multi-joint arm;Automatic height gauge;Manual height gauge;Dial gauge;Marble platform;Roughness measurement |

|

Application

|

Industrial/ auto/ Motorcycle/ electronics/ electric power/ Toys/ Sports/ Machinery equipment etc.

|

|

Springs

|

|

|

Quality certification

|

IATF 16949:2016, ISO 14001:2015, ISO9001:2015, OHSAS 18001:2007,ROHS

|

Conclusion

In sumarry, Double Twist Torsion Springs are an essential component of mechanical engineering. They are used in a wide range of applications and offer many advantages over other types of springs. The manufacturing process is complex, but it is necessary to ensure that the final product is of high quality. As mechanical engineering continues to evolve, Double Twist Torsion Springs will continue to play an important role in the success of many industrial applications.